![]()

![]()

For the latest product updates, visit us online at johnsoncontrols.com,

search commercial refrigeration

Refrigeration Products Catalog

Single-Stage Electromechanical Temperature Controls . . . . . . . . . . . . . . . . . . . R-17 Single-Stage Electronic Temperature Controls . . . . . . . . . . . . . . . . . . . . . . . . . R-44

Multi-Stage Electromechanical Temperature Controls . . . . . . . . . . . . . . . . . . . . R-59

Temperature Control Sensors and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . R-79

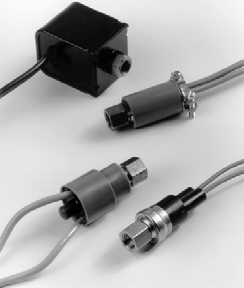

Standard Electromechanical Pressure Controls . . . . . . . . . . . . . . . . . . . . . . . . . R-85

Single-Stage Electronic Pressure Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . R-103 Electromechanical Lube Oil and Differential Pressure Controls . . . . . . . . . . . . R-105 Electronic Lube Oil and Differential Pressure Controls . . . . . . . . . . . . . . . . . . R-111 Pressure Sensors and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R-114

Single-Stage Electromechanical Temperature Controls . . . . . . R-17

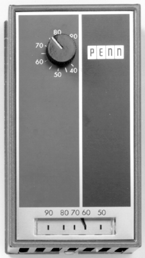

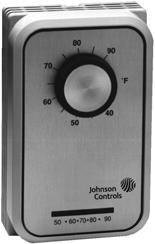

A11 Series Low Temperature Cutout

Controls . . . . . . . . . . . . . . . . . . . . . . . . R-17

A19 Series Remote Bulb Control . . . . . . . . R-19 A19 Series High Range Temperature

Control . . . . . . . . . . . . . . . . . . . . . . . . . R-21

A19 Series Thermostat for Crop Drying. . R-22 A19 Series Hot Water Temperature Control

(Well Immersion) . . . . . . . . . . . . . . . . . R-23

A19 Temperature Control Less Enclosure (SPDT, Close Differential) . . . . . . . . . . R-24

A19 Series Thermostat for Hazardous Locations . . . . . . . . . . . . . . . . . . . . . R-25

Thermostat. . . . . . . . . . . . . . . . . . . . . . R-26

A19 Thermostat for Portable Heaters (Chain Mount and Drop Cord

Electrical Connection) . . . . . . . . . . . . . R-27 A19 Thermostat for Portable Cooling

Drop Cord Electrical Connection) . . . . R-28 A19 Series Automatic Changeover with

Strap-On Mounting. . . . . . . . . . . . . . . . R-29

Temperature Controls . . . . . . . . . . . . R-30 A19 Flange Mounted Duct Thermostat . . . R-31 A19 Series Fan or Cutout Control

(Liquid Expansion Bulb) . . . . . . . . . . . . R-32

A19 Temperature Control with Rainproof Enclosure . . . . . . . . . . . . . . . . . . . . . R-33

A19 Agricultural/Industrial Thermostat with NEMA 4X Enclosure . . . . . . . . . . . . . . R-34

A19 Temperature Control with NEMA 4X Enclosure (Remote Bulb). . . . . . . . . . R-36

A19 Water Chiller Control with Locked

Cut-Out/Adjustable Cut-In . . . . . . . . . . R-37 A19 Defrost Duration and Fan Delay

Control . . . . . . . . . . . . . . . . . . . . . . . . R-38

A25 Series Warm Air Limit Control with

Manual Reset . . . . . . . . . . . . . . . . . . . R-39

A70 Series Four-Wire, Two-Circuit

Temperature Control . . . . . . . . . . . . . R-40 A72 Series Two-Pole Heavy Duty

(Adjustable Differential) . . . . . . . . . . . . R-41 A72 Series Cooling Tower or Evaporative

Condenser Controls (Single-Stage

Outdoor Enclosure) . . . . . . . . . . . . . . . R-42 A72AA Coiled Bulb Space Thermostat

(Cooling) . . . . . . . . . . . . . . . . . . . . . . . R-43

Temperature Controls . . . . . . R-44

A421 Series Electronic Temperature

Controls . . . . . . . . . . . . . . . . . . . . . . . R-44

A421 Series Electronic Temperature

Controls with Integral Power Cord . . . R-47 A421 Series Electronic Temperature

Controls with Off-Cycle Defrost . . . . . R-50

A421 Series Electronic Temperature

Controls with Integral Cycle Timer . . . R-53 MR Series Defrost Control Modules . . . . . R-56 MR4PMUHV Electronic

Temperature/Defrost Control with

Relay Pack . . . . . . . . . . . . . . . . . . . . . R-58

Multi-Stage Electromechanical Temperature Controls . . . . . . R-59

A28 Series Two-Stage Temperature

Control. . . . . . . . . . . . . . . . . . . . . . . . . R-59

Two Stage Temperature Control . . . . . . . . R-59 A28 Series Two-Stage Flange Mounted

Duct Thermostat . . . . . . . . . . . . . . . . . R-61

A28 Two-Stage Industrial Thermostat (Watertight and Dusttight) . . . . . . . . . . R-62

A28 Two-Stage Temperature Control with Weatherproof Enclosure . . . . . . . . . . . R-63

Table of Contents

A28 Two-Stage Agricultural Thermostat with NEMA 4X Enclosure . . . . . . . . . . . . . . R-64

A36 Series Four-Stage Remote Bulb Thermostats . . . . . . . . . . . . . . . . . . . . . R-65

S26 Series Switching Subbase . . . . . . . . R-66 T22/T25/T26 Series Line Voltage Wall

Thermostat (Heating, Cooling, or

Heating and Cooling) . . . . . . . . . . . . R-67 Typical Wiring Diagram and Electrical

Ratings for Line Voltage Thermostats . R-69

T23 Series Fan Coil Thermostat

(with Fan and System Selectors) . . . . . R-70 T28 Series Fan Coil Thermostat (with or

without Fan Selector Switches) . . . . . . R-71

T46 Series Fan Coil Thermostat . . . . . . . R-72

Temperature Controls . . . . . . . R-74

MS Series Temperature Stage Control

Modules . . . . . . . . . . . . . . . . . . . . . . . . R-74

MS Series Single-Stage Control Modules

with Voltage Input . . . . . . . . . . . . . . . . R-76 MS4PMUHVT Multi-Stage Electronic

Temperature Control with Relay Pack . R-78

Temperature Control Sensors and Accessories . . . . . . . . . . . . . . . R-79

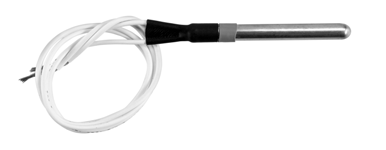

A99B Series Temperature Sensor . . . . . R-79 Bulb Wells . . . . . . . . . . . . . . . . . . . . . . . . . R-80

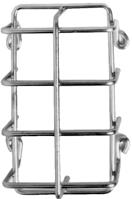

G Series Thermostat and Humidistat

Guards . . . . . . . . . . . . . . . . . . . . . . . . R-81 T22, T25, T26, T28, T46, and T91

Accessories . . . . . . . . . . . . . . . . . . . . . R-83

T91 Series Room Temperature Sensor . . . R-84

Pressure Controls . . . . . . . . . . R-85

P10 Series Low Pressure Control . . . . . . . R-85 P20 Series Air Conditioning/Pressure

Cutout Control . . . . . . . . . . . . . . . . . . . R-86

P29 Series Low Pressure Control with

Time Delay. . . . . . . . . . . . . . . . . . . . . . R-88

P47 Series Steam Pressure Limit Control. R-89 P67 Series Low Pressure Control . . . . . . R-90 P70, P72 Approximate Low Pressure

Settings for Typical Applications . . . . . R-91

P70, P72, and P170 Series Controls for

Low Pressure Applications . . . . . . . . . R-92 P70, P72, and P170 Series Controls for

High Pressure Applications . . . . . . . . . R-96

P70, P72, and P170 Series Controls for

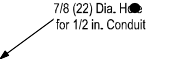

Dual Pressure Applications . . . . . . . . R-100

Pressure Controls . . . . . . . . . R-103

P470 Electronic Pressure Control with

Display . . . . . . . . . . . . . . . . . . . . . . . R-103

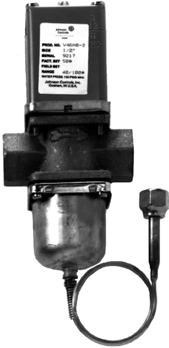

Electromechanical Lube Oil and Differential Pressure

Controls . . . . . . . . . . . . . . . . . R-105

P28 Series Lube Oil Pressure Cutout

Control with Time Delay . . . . . . . . . . R-105 P32 Series Sensitive Pressure Switch . . R-106 P45 Series Lube Oil Pressure Cutout

Control with Time Delay . . . . . . . . . . R-107

P74 Series Differential Pressure Control. R-108 P128 and P145 Series Lube Oil Pressure

Controls . . . . . . . . . . . . . . . . . . . . . . . R-109

P12 Series Differential Pressure

Controls . . . . . . . . . . . . . . . . . . . . . . . R-110

Electronic Lube Oil and Differential Pressure

Controls . . . . . . . . . . . . . . . . . R-111

P545 Series Electronic Lube Oil Control . R-111 CST29A Adaptor Block for Carlyle®

Compressors . . . . . . . . . . . . . . . . . . . R-113

Accessories . . . . . . . . . . . . . . R-114

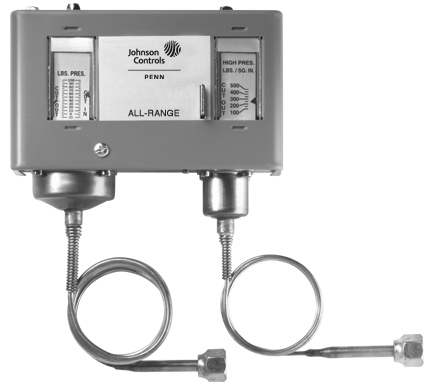

Replacement Timing Relays for P28 and

P29 Lube Oil Controls . . . . . . . . . . . R-114

Table of Contents

P100 Series Encapsulated Pressure

Switches. . . . . . . . . . . . . . . . . . . . . . . R-115

P499 Series Electronic Pressure

Transducers . . . . . . . . . . . . . . . . . . . R-119

R310A Series Current Sensing Switch . . R-122 Universal Mounting Brackets . . . . . . . . . . R-123 SEC99A UltraCap Armored Capillary . . . R-124

Refrigerant Sensors/Monitors . R-125

Detector . . . . . . . . . . . . . . . . . . . . . . . R-125

Accessories and Replacement Parts . R-126

Controls. . . . . . . . . . . . . . . . . R-127

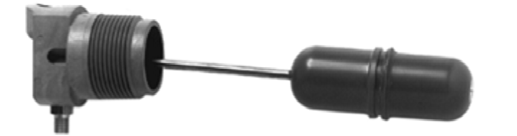

F59 Series Sump Pump Switch . . . . . . . . R-127 F261 Series Fluid Flow Switches . . . . . . R-128 F262 Airflow Switch . . . . . . . . . . . . . . . . R-130

F263 Series Liquid Level Float

Switches. . . . . . . . . . . . . . . . . . . . . . . R-132

F61 and F62 Series Replacement

Paddles . . . . . . . . . . . . . . . . . . . . . . . R-134

F92 Series Air Volume Controls for

Shallow Wells . . . . . . . . . . . . . . . . . . R-135

F93 Series Air Volume Controls for

Deep Wells . . . . . . . . . . . . . . . . . . . . R-136

Motor Speed Controls . . . . . . . . R-137

P266 Series Single-Phase Condenser

Fan Speed Control . . . . . . . . . . . . . . R-137 P66/S66 Series Controls to P266 Series

Controls Replacement Guide . . . . . . R-140

VFD68 Variable Frequency Drives . . . . . R-142

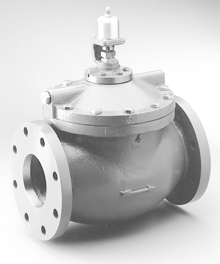

Valves and Valve Accessories . R-145

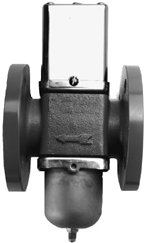

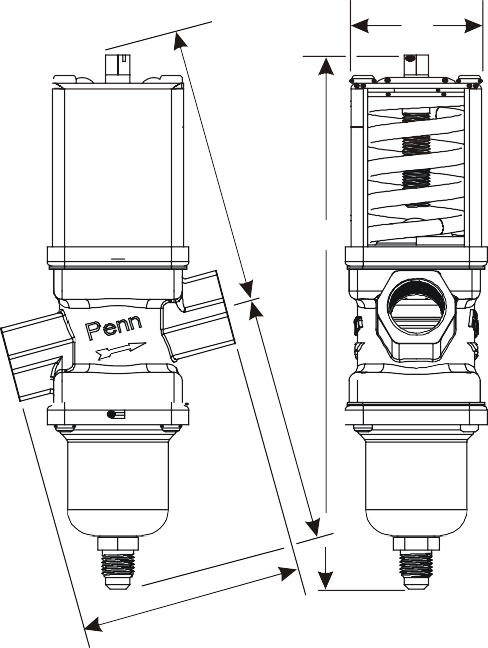

V43/V243 Series Pressure-Actuated

Water-Regulating Valves . . . . . . . . . . R-145 V46 Series Pressure Actuated

Water-Regulating Valve . . . . . . . . . . . R-151

V46N Series Reverse Acting Valve . . . . . R-154

V46 Series Valve Sizing Information—90% Open Method. . . . . . . . . . . . . . . . . R-155

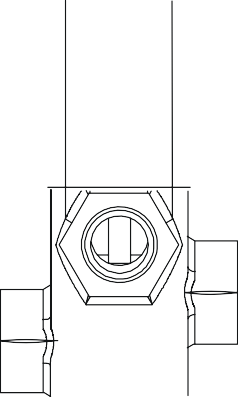

V46 Series Valve Dimensions . . . . . . . . . R-156 V47 Series Temperature Actuated

Modulating Valve. . . . . . . . . . . . . . . . R-157

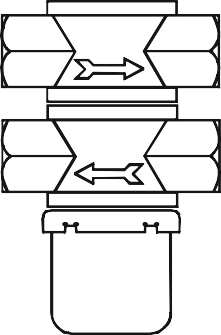

V47N Series Reverse Acting Valve. . . . . R-159 V48 Series Three-Way Water

Regulating Valve . . . . . . . . . . . . . . . . R-160

V146 Series Two-Way Pressure-Actuated Water-Regulating Valves . . . . . . . . . R-161

V148 Series Three-Way Pressure-Actuated Water-Regulating Valves . . . . . . . . . R-166

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants . . . . . . . R-171 V248 Series Three-Way Pressure-Actuated

High-Pressure Refrigerants . . . . . . . R-181 STT Water Valve Renewal Kit for

V46, V47, and V48 Series Valves . . . R-188

Companion Flanges and Gaskets for

V43, V46, and V47 Series Valves . . . R-189

Relays and Transformers . . . . . R-190

Y63, Y64, Y65, Y66, and Y69 Series

Transformers . . . . . . . . . . . . . . . . . . . R-190

System 450 Control Series . . . . R-192

System 450™ Series Modular Controls . R-192 System 450™ Series Control Module with

Network Communications . . . . . . . . R-203

System 450™ Reset Control Modules with

Real-Time Clock and Relay Output. . R-206 System 450™ Control Modules with

Analog Output . . . . . . . . . . . . . . . . . R-208

System 450™ Control Modules with

Relay Output . . . . . . . . . . . . . . . . . . R-210

System 450™ Control Module with

Hybrid Analog Output . . . . . . . . . . . . R-212 System 450™ Expansion Modules with

Analog Output . . . . . . . . . . . . . . . . . R-214

System 450™ Expansion Modules with

Relay Output . . . . . . . . . . . . . . . . . . R-216

Table of Contents

System 450™ Power Module . . . . . . . . . R-218 System 450™ Compatible Sensors,

Transducers, and Accessories . . . . . R-219

Cross-Reference . . . . . . . . . . . . . R-223

Ranco® Refrigeration Cross-Reference . R-223 ALCO® Cross Reference . . . . . . . . . . . . R-231

Numerics

210-604R . . . . . . . . . . . . . . . . . . . . . . . . . R-87

246-423 . . . . . . . . . . . . . . R-153, R-158, R-189

246-424 . . . . . . . . . . . . . . . . . . . . . . . . . . R-189

246-425 . . . . . . . . . . . . . . R-153, R-158, R-189

271-51 . . . . .R-88, R-107, R-109, R-112, R-123

426-424 . . . . . . . . . . . . . . . . . . . . R-153, R-158

A

A19AAB-10C . . . . . . . . . . . . . . . . . . . . . . . R-21

A19AAB-4C . . . . . . . . . . . . . . . . . . . . . . . . R-21

A19AAB-7C . . . . . . . . . . . . . . . . . . . . . . . . R-21

A19AAC-4C . . . . . . . . . . . . . . . . . . . . . . . R-19

A19AAC-9C . . . . . . . . . . . . . . . . . . . . . . . R-21

A19AAD-12C . . . . . . . . . . . . . . . . . . . . . . R-19

A19AAD-5C . . . . . . . . . . . . . . . . . . . . . . . R-19

A19AAE-3C . . . . . . . . . . . . . . . . . . . . . . . . R-22

A19AAF-12C . . . . . . . . . . . . . . . . . . . . . . . R-19

A19AAF-20C . . . . . . . . . . . . . . . . . . . . . . . R-19

A19AAF-21C . . . . . . . . . . . . . . . . . . . . . . . R-19

A19AAT-2C . . . . . . . . . . . . . . . . . . . . . . . . R-28

A19ABA-40C . . . . . . . . . . . . . . . . . . . . . . . R-19

A19ABB-2C . . . . . . . . . . . . . . . . . . . R-21, R-22

A19ABB-7C . . . . . . . . . . . . . . . . . . . . . . . . R-21

A19ABC-11C . . . . . . . . . . . . . . . . . . . . . . R-23

A19ABC-12C . . . . . . . . . . . . . . . . . . . . . . R-23

A19ABC-24C . . . . . . . . . . . . . . . . . . . . . . R-19

A19ABC-36C . . . . . . . . . . . . . . . . . . . . . . R-19

A19ABC-37C . . . . . . . . . . . . . . . . . . . . . . R-19

A19ABC-4C . . . . . . . . . . . . . . . . . . . . . . . R-19

A19ABC-74C . . . . . . . . . . . . . . . . . . . . . . R-19

A19ACA-14C . . . . . . . . . . . . . . . . . . . . . . R-19

A19ACA-15C . . . . . . . . . . . . . . . . . . . . . . R-19

A19ADB-1C . . . . . . . . . . . . . . . . . . . . . . . R-19

A19ADB-2C . . . . . . . . . . . . . . . . . . . . . . . R-23

A19ADN-1C . . . . . . . . . . . . . . . . . . . . . . . R-19

A19AGF-31C . . . . . . . . . . . . . . . . . . . . . . R-24

A19ANC-1C . . . . . . . . . . . . . . . . . . . . . . . R-33

A19AUC-1C . . . . . . . . . . . . . . . . . . . . . . . R-25

A19AUC-2C . . . . . . . . . . . . . . . . . . . . . . . R-25

A19AUC-3C . . . . . . . . . . . . . . . . . . . . . . . R-25

A19AUC-4C . . . . . . . . . . . . . . . . . . . . . . . R-25

A19BAB-3C . . . . . . . . . . . . . . . . . . . . . . . . R-26

A19BAC-1C . . . . . . . . . . . . . . . . . . . . . . . R-26

A19BAF-1C . . . . . . . . . . . . . . . . . . . . . . . . R-26

A19BAG-1C . . . . . . . . . . . . . . . . . . . . . . . R-27

A19BBC-2C . . . . . . . . . . . . . . . . . . . . . . . R-26

A19BUC-2C . . . . . . . . . . . . . . . . . . . . . . . R-25

A19CAC-1C . . . . . . . . . . . . . . . . . . . . . . . R-29

A19CAC-2C . . . . . . . . . . . . . . . . . . . . . . . R-29

A19DAC-10C . . . . . . . . . . . . . . . . . . . . . . R-30

A19DAC-12C . . . . . . . . . . . . . . . . . . . . . . R-30

A19DAC-1C . . . . . . . . . . . . . . . . . . . . . . . R-30

A19DAC-9C . . . . . . . . . . . . . . . . . . . . . . . R-30

A19DAF-2C . . . . . . . . . . . . . . . . . . . . . . . R-30

A19EAF-1C . . . . . . . . . . . . . . . . . . . . . . . R-31

A19EAF-2C . . . . . . . . . . . . . . . . . . . . . . . R-31

A19EBA-1C . . . . . . . . . . . . . . . . . . . . . . . R-32

A19EBB-1C . . . . . . . . . . . . . . . . . . . . . . . R-32

A19EBC-1C . . . . . . . . . . . . . . . . . . . . . . . R-32

A19EDB-1C . . . . . . . . . . . . . . . . . . . . . . . R-32

A19KNC-1C . . . . . . . . . . . . . . . . . . . . . . . R-35

A19PRC-1C . . . . . . . . . . . . . . . . . . . . . . . R-34

A19QSC-1C . . . . . . . . . . . . . . . . . . . . . . . R-36

A19QSC-2C . . . . . . . . . . . . . . . . . . . . . . . R-36

A19QSC-3C . . . . . . . . . . . . . . . . . . . . . . . R-36

A19QSC-4C . . . . . . . . . . . . . . . . . . . . . . . R-36

A19ZBA-1C . . . . . . . . . . . . . . . . . . . . . . . R-37

A19ZBC-2C . . . . . . . . . . . . . . . . . . . . . . . R-38

A25AN-1C . . . . . . . . . . . . . . . . . . . . . . . . R-39

A25AP-1C . . . . . . . . . . . . . . . . . . . . . . . . R-39

A25CN-1C . . . . . . . . . . . . . . . . . . . . . . . . R-39

A25CP-1C . . . . . . . . . . . . . . . . . . . . . . . . R-39

A28AA-28C . . . . . . . . . . . . . . . . . . . . . . . R-59

A28AA-29C . . . . . . . . . . . . . . . . . . . . . . . R-59

A28AA-36C . . . . . . . . . . . . . . . . . . . . . . . R-59

A28AA-37C . . . . . . . . . . . . . . . . . . . . . . . R-59

A28AA-4C . . . . . . . . . . . . . . . . . . . . . . . . R-59

A28AA-9C . . . . . . . . . . . . . . . . . . . . . . . . R-59

A28AB-1C . . . . . . . . . . . . . . . . . . . . . . . . R-59

A28AJ-4C . . . . . . . . . . . . . . . . . . . . . . . . . R-59

A28AK-1C . . . . . . . . . . . . . . . . . . . . . . . . R-61

A28AK-2C . . . . . . . . . . . . . . . . . . . . . . . . R-61

A28KA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-62

A28MA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-63

A28MA-2C . . . . . . . . . . . . . . . . . . . . . . . . R-63

A28PA-2C . . . . . . . . . . . . . . . . . . . . . . . . R-64

A28PJ-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-64

A36AHA-50C . . . . . . . . . . . . . . . . . . . . . . R-65

A36AHA-52C . . . . . . . . . . . . . . . . . . . . . . R-65

A36AHA-58C . . . . . . . . . . . . . . . . . . . . . . R-65

A36AHB-33C . . . . . . . . . . . . . . . . . . . . . . R-65

A421ABC-02C . . . . . . . . . . . . . . . . . . . . . R-45

Note: Page numbers in italics denote pages where the product code number appears, but not as the main part.

Code Number Index

A421ABC-03C . . . . . . . . . . . . . . . . . . . . . R-45

A421ABC-04C . . . . . . . . . . . . . . . . . . . . . R-45

A421ABC-06C . . . . . . . . . . . . . . . . . . . . . R-45

A421ABD-02C . . . . . . . . . . . . . . . . . . . . . R-51

A421ABG-02C . . . . . . . . . . . . . . . . . . . . . R-48

A421ABJ-02C . . . . . . . . . . . . . . . . . . . . . . R-48

A421ABT-02C . . . . . . . . . . . . . . . . . . . . . . R-54

A421AEC-01C . . . . . . . . . . . . . . . . . . . . . R-45

A421AEC-02C . . . . . . . . . . . . . . . . . . . . . R-45

A421AED-01C . . . . . . . . . . . . . . . . . . . . . R-51

A421AED-02C . . . . . . . . . . . . . . . . . . . . . R-51

A421AEJ-01C . . . . . . . . . . . . . . . . . . . . . . R-48

A421AET-01C . . . . . . . . . . . . . . . . . . . . . . R-54

A421GBF-02C . . . . . . . . . . . . . . . . . . . . . R-45

A421GEF-01C . . . . . . . . . . . . . . . . . . . . . R-45

A421GEF-02C . . . . . . . . . . . . . . . . . . . . . R-45

A70GA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-40

A70GA-2C . . . . . . . . . . . . . . . . . . . . . . . . . R-40

A70HA-14C . . . . . . . . . . . . . . . . . . . . . . . . R-40

A70HA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-40

A70HA-2C . . . . . . . . . . . . . . . . . . . . . . . . . R-40

A70KA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-40

A72AA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-41

A72AA-2C . . . . . . . . . . . . . . . . . . . . . . . . . R-41

A72AA-3C . . . . . . . . . . . . . . . . . . . . . . . . . R-41

A72AA-4C . . . . . . . . . . . . . . . . . . . . . . . . . R-43

A72AE-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-42

A72AP-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-41

A72CE-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-42 A99BA-200C . . . . . . R-74, R-79, R-195, R-220 A99BB-200C . . . . . . . . . . . . . R-58, R-74, R-78,

. . . . . . . . . . . . . . . . . . . . R-79, R-195, R-220

A99BB-25C . . . . . . . . . . . . R-79, R-195, R-220

A99BB-300C . . . . . . R-74, R-79, R-195, R-220

A99BB-500C . . . . . . R-74, R-79, R-195, R-220

A99BB-600C . . . . . . R-74, R-79, R-195, R-220

A99BC-1500C . . . . . . . . . . R-79, R-195, R-220

A99BC-25C . . . . . . . . . . . . R-79, R-195, R-220

A99BC-300C . . . . . . . . . . . R-79, R-195, R-220

A99BC-500C . . . . . . . . . . . . . . . . . . . . . . . R-79

A99-CLP-1 . . . . . . . . . . . . R-79, R-196, R-220

ADP11A-600R . . . . . . . . . R-79, R-196, R-220

B

BKT16A-600R . . . . . . . . . . . . . . . . . . . . . . R-85

BKT182-1R . . . . . . . . . . . . . . . . . . . . . . . R-106

BKT229-1R . . . . . . . . . . . . . . . . . . . . . . . R-106

BKT287-1R . . . . . . . . . . . R-195, R-204, R-207,

. . . . . . . . . . . . . . . . . . . R-208, R-210, R-213,

. . . . . . . . . . . . . . . . . . . . R-214, R-216, R-218

BKT287-2R . . . . . . . . . . . R-195, R-204, R-207,

. . . . . . . . . . . . . . . . . . . R-208, R-210, R-213,

. . . . . . . . . . . . . . . . . . . . R-214, R-216, R-218

BKT287-3R . . . . . . . . . . . R-195, R-204, R-207,

. . . . . . . . . . . . . . . . . . . R-208, R-210, R-213,

. . . . . . . . . . . . . . . . . . . . R-214, R-216, R-218

BKT287-4R . . . . . . . . . . . R-195, R-204, R-207,

. . . . . . . . . . . . . . . . . . . R-208, R-210, R-213,

. . . . . . . . . . . . . . . . . . . . R-214, R-216, R-218 BKT38A-600R . . . . . . . . . R-107, R-109, R-123 BKT38A-601R . . . . . . . . . . . . . . . . . . . . R-109

BKT48A-600R . . . . . . . . . . . . . . . . . . . . . R-72

BOX10A-600R . . . . . . . . . . R-79, R-195, R-220

C

C450CBN-3C . . . . . . . . . . . . . . . .R-195, R-210

C450CCN-3C . . . . . . . . . . . . . . . .R-195, R-210

C450CEN-1C . . . . . . . . . . . . . . . .R-195, R-204

C450CPN-3C . . . . . . . . . . . . . . . .R-195, R-208

C450CPW-100C . . . . . . . . . . . . . .R-195, R-213

C450CQN-3C . . . . . . . . . . . . . . . .R-195, R-208

C450CRN-1C . . . . . . . . . . . . . . . .R-195, R-204

C450RBN-3C . . . . . . . . . . . . . . . .R-195, R-207

C450RCN-3C . . . . . . . . . . . . . . . .R-195, R-207

C450SBN-3C . . . . . . . . . . . . . . . .R-195, R-216

C450SCN-3C . . . . . . . . . . . . . . . .R-195, R-216

C450SPN-1C . . . . . . . . . . . . . . . .R-195, R-214

C450SQN-1C . . . . . . . . . . . . . . . .R-195, R-214

C450YNN-1C . . . . . . . . . . . . . . . .R-195, R-218

CSE57A-600 . . . . . . . . . . . . . . . . . . . . . . R-65

CST29A-600C . . . . . . . . . . . . . . . . . . . . R-113

CVR17A-620R . . . . . . . . . . . . R-40, R-41, R-43

CVR17A-621R . . . . . . . . . . . . . . . . .R-40, R-41

CVR28A-617R . . . . . . R-20, R-21, R-23, R-24,

. . . . . . . . . . . . . . . . . . . . . . . R-26, R-29, R-60

CVR28A-618R . . . . . . R-20, R-21, R-23, R-24,

. . . . . . . . . . . . . . . . . . R-26, R-31, R-32, R-60

CVR61A-600R . . . . . . . . . . . . . . . . . . . . . R-37

CVR88A-600R . . . . . . . . . . . . . . . . . . . . . R-72

Code Number Index

D

DBK10A-600R . . . . . . . . . . . . . . . . . . . . R-147

DBK10A-601R . . . . . . . . . . . . . . R-147, R-148

DBK10A-602R . . . . . . . . . . . . . . . . . . . . R-147

DBK10A-603R . . . . . . . . . . . . . . . . . . . . R-147

DBK11A-600R . . . . . . . . . . . . . . . . . . . . R-147

DBK11A-601R . . . . . . . . . . . . . . . . . . . . R-147

DBK11A-602R . . . . . . . . . . . . . . . . . . . . R-147

DBK11A-603R . . . . . . . . . . . . . . . . . . . . R-147

DPM17A-600R . . . . . . . . . . . . . . . . . . . . R-188

DPM17A-601R . . . . . . . . . . . . . . . . . . . . R-188

DPM18A-600R . . . . . . . . . . . . . . . . . . . . R-147

DPM18A-601R . . . . . . . . . . . . . . . . . . . . R-147

DPM18A-602R . . . . . . . . . . . . . . . . . . . . R-147

DPM18A-603R . . . . . . . . . . . . . . . . . . . . R-147

DPT2650-005D-AB . . . . . . . . . . . R-196, R-221

DPT2650-0R5D-AB . . . . . . . . . . R-196, R-221

DPT2650-10D-AB . . . . . . . . . . . . R-196, R-221

DPT2650-2R5D-AB . . . . . . . . . . R-196, R-221

DPT2650-R25B-AB . . . . . . . . . . . R-196, R-221

DSC16A-600R . . . . . . . . . . . . . . . . . . . . R-147

DSC16A-601R . . . . . . . . . . . . . . . . . . . . R-147

DSC16A-602R . . . . . . . . . . . . . . R-147, R-148

DSC16A-603R . . . . . . . . . . . . . . . . . . . . R-147

F

F261KAH-V01C . . . . . . . . . . . . . . . . . . . R-128

F261KEH-V01C . . . . . . . . . . . . . . . . . . . R-128

F261KFH-V01C . . . . . . . . . . . . . . . . . . . R-128

F261KFH-V02C . . . . . . . . . . . . . . . . . . . R-128

F261MAH-V01C . . . . . . . . . . . . . . . . . . . R-128

F261MAL-V01C . . . . . . . . . . . . . . . . . . . R-128

F261MEH-V01C . . . . . . . . . . . . . . . . . . . R-128

F261MFH-V01C . . . . . . . . . . . . . . . . . . . R-128

F262KDH-01C . . . . . . . . . . . . . . . . . . . . R-130

F263MAC-V01C . . . . . . . . . . . . . . . . . . . R-132

F263MAP-V01C . . . . . . . . . . . . . . . . . . . R-132

F59A-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-127

F59A-2C . . . . . . . . . . . . . . . . . . . . . . . . . R-127

F59H-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-127

FLG15A-600 . . . . . . . . . . . . . . . . . . . . . . R-189

FLG15A-601 . . . . . . . . . . . . . . . . . . . . . . R-189

FTG13A-600R . . . . . . . . . . . . R-20, R-21, R-37,

. . . . . . . . . . . . . . . . . . . . . . R-41, R-59, R-80

FTG18A-600R . . . . . . . . . . . . . . . . . . . . . R-106

G

GRD10-1R . . . . . . . . . . . . . . . . . . . . . . . . R-81

GRD10A-600 . . . . . . . . . . . . . . . . . . . . . . R-81

GRD10A-601 . . . . . . . . . . . . . . . . . . . . . . R-81

GRD10A-606 . . . . . . . . . . . . . . . . . . . . . . R-81

GRD10A-608 . . . . . . . . . . . . . . . . . . . . . . R-81

GRD10A-609 . . . . . . . . . . . . . . . . . . . . . . R-81

H

HE-6300 . . . . . . . . . . . . . . . . . . . . . . . . . . R-76

HE-6310 . . . . . . . . . . . . . . . . . . . . . . . . . . R-76

HE-67S3-0N00P . . . . . . . . . . . . . .R-196, R-221

HE-67S3-0N0BT . . . . . . . . . . . . .R-196, R-221

HE-68N2-0N00WS . . . . . . . . . . . .R-196, R-221

HE-68N3-0N00WS . . . . . . . . . . . .R-196, R-221

K

KEY12A-600 . . . . . . . . . . . . . . . . . . . . . . . R-81

KIT14A-612 . . . . . . . . . . . R-153, R-158, R-189

KIT14A-613 . . . . . . . . . . . R-153, R-158, R-189

KIT14A-614 . . . . . R-146, R-153, R-158, R-189 KIT21A-600 . . . . . . . . . . . . . . . . . . . . . . R-134

KIT21A-601 . . . . . . . . . . . . . . . . . . . . . . R-134

KITP545-82C . . . . . . . . . . . . . . . .R-112, R-113

KNB17A-600R . . . . . . . . . . . . . . . . . . . . . R-83

KNB20A-600R . . . . . . . . . . . . . . . . . . . . . R-83

KNB20A-602R . . . . . . . . . . . R-20, R-21, R-23,

. . . . . . . . . . . . . . . . . . . . . . . R-24, R-26, R-60

KNB26A-600R . . . . . . . . . . . . . . . . .R-72, R-83

M

MR1DR24-11C . . . . . . . . . . . . . . . . . . . . . R-56

MR2DR24-11C . . . . . . . . . . . . . . . . . . . . . R-56

MR2PM24-11C . . . . . . . . . . . . . . . . . . . . . R-56

MR4DR24-12C . . . . . . . . . . . . . . . . . . . . . R-56

MR4PM12C-12C . . . . . . . . . . . . . . . . . . . R-58

MR4PM24-12C . . . . . . . . . . . . . . . . . . . . . R-56

MR4PMUHV-12C . . . . . . . . . . . . . . . . . . . R-58

MS1DR24T-11C . . . . . . . . . . . . . . . . . . . . R-74

MS1DR24V-11C . . . . . . . . . . . . . . . . . . . . R-76

MS2DR24T-11C . . . . . . . . . . . . . . . . . . . . R-74

MS2PM24T-11C . . . . . . . . . . . . . . . . . . . . R-74

MS4DR24T-11C . . . . . . . . . . . . . . . . . . . . R-74

MS4PM12CT-11C . . . . . . . . . . . . . . . . . . R-78

Code Number Index

MS4PM24T-11C . . . . . . . . . . . . . . . . . . . . R-74

MS4PMUHVT-11C . . . . . . . . . . . . . . . . . . R-78

P

P10BC-7C . . . . . . . . . . . . . . . . . . . . . . . . . R-85

P10BG-3C . . . . . . . . . . . . . . . . . . . . . . . . . R-85

P10BJ-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-85

P10FC-4C . . . . . . . . . . . . . . . . . . . . . . . . . R-85

P10PA-11C . . . . . . . . . . . . . . . . . . . . . . . . R-85

P128AA-17C . . . . . . . . . . . . . . . . . . . . . . R-109

P128AA-1C . . . . . . . . . . . . . . . . . . . . . . . R-109

P128AA-2C . . . . . . . . . . . . . . . . . . . . . . . R-109

P12AA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-110 P145NCA-12C . . . . . . . . . . . . . . R-107, R-109

P145NCA-82C . . . . . . . . . . . . . . R-107, R-109

P145NCB-12C . . . . . . . . . . . . . . R-107, R-109

P145NCB-82C . . . . . . . . . . . . . . R-107, R-109

P170AA-118C . . . . . . . . . . . . . . . . . . . . . . R-96

P170AA-2C . . . . . . . . . . . . . . . . . . . . . . . . R-97

P170AA-400C . . . . . . . . . . . . . . . . . . . . . . R-97

P170AB-12C . . . . . . . . . . . . . . . . . . . . . . . R-93

P170AB-2C . . . . . . . . . . . . . . . . . . . . . . . . R-93

P170CA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-93

P170CA-3C . . . . . . . . . . . . . . . . . . . . . . . . R-96

P170CA-400C . . . . . . . . . . . . . . . . . . . . . . R-97

P170DA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-96

P170DA-400C . . . . . . . . . . . . . . . . . . . . . . R-97

P170EA-14C . . . . . . . . . . . . . . . . . . . . . . . R-93

P170KA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-96

P170LB-1C . . . . . . . . . . . . . . . . . . . . . . . R-101

P170LB-6C . . . . . . . . . . . . . . . . . . . . . . . R-100

P170MA-18C . . . . . . . . . . . . . . . . . . . . . R-100

P170MA-1C . . . . . . . . . . . . . . . . . . . . . . R-101

P170NA-1C . . . . . . . . . . . . . . . . . . . . . . . R-101

P170SA-1C . . . . . . . . . . . . . . . . . . . . . . . R-100

P20BB-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-86

P20DB-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-86

P20EB-18C . . . . . . . . . . . . . . . . . . . . . . . . R-86

P20EB-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-86

P20EB-2C . . . . . . . . . . . . . . . . . . . . . . . . . R-86

P20GB-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-86

P28AA-17C . . . . . . . . . . . . . . . . . . . . . . . R-105

P28AA-18C . . . . . . . . . . . . . . . . . . . . . . . R-105

P28AA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-105

P28AA-2C . . . . . . . . . . . . . . . . . . . . . . . . R-105

P28AN-1C . . . . . . . . . . . . . . . . . . . . . . . . R-105

P28DA-1C . . . . . . . . . . . . . . . . . . . . . . . R-105

P28DN-1C . . . . . . . . . . . . . . . . . . . . . . . R-105

P28GA-2C . . . . . . . . . . . . . . . . . . . . . . . R-105

P28NA-5C . . . . . . . . . . . . . . . . . . . . . . . R-105

P29NC-2C . . . . . . . . . . . . . . . . . . . . . . . . R-88

P29NC-3C . . . . . . . . . . . . . . . . . . . . . . . . R-88

P29NC-49C . . . . . . . . . . . . . . . . . . . . . . . R-88

P29NC-53C . . . . . . . . . . . . . . . . . . . . . . . R-88

P29NF-1C . . . . . . . . . . . . . . . . . . . . . . . . R-88

P32AC-1C . . . . . . . . . . . . . . . . . . . . . . . R-106

P32AC-2C . . . . . . . . . . . . . . . . . . . . . . . R-106

P32AF-1C . . . . . . . . . . . . . . . . . . . . . . . . R-106

P32AF-2C . . . . . . . . . . . . . . . . . . . . . . . . R-106

P400AD-1C . . . . . . . . . . . . . . . . .R-112, R-113

P400AD-2C . . . . . . . . . . . . . . . . . . . . . . R-112

P400BD-1C . . . . . . . . . . . . . . . . . . . . . . R-112

P45NAA-10C . . . . . . . . . . . . . . . . . . . . . R-107

P45NAA-5C . . . . . . . . . . . . . . . . . . . . . . R-107

P45NCA-12C . . . . . . . . . . . . . . . . . . . . . R-107

P45NCA-82C . . . . . . . . . . . . . . . . . . . . . R-107

P47AA-13C . . . . . . . . . . . . . . . . . . . . . . . R-89

P47AA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-89

P47AA-4C . . . . . . . . . . . . . . . . . . . . . . . . R-89

P47AB-3C . . . . . . . . . . . . . . . . . . . . . . . . R-89

P47BA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-89

P47BA-6C . . . . . . . . . . . . . . . . . . . . . . . . R-89

P47EA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-89

P47GA-9C . . . . . . . . . . . . . . . . . . . . . . . . R-89 P499RAP-101C . . . . . . . . . . . . . .R-197, R-222

P499RAP-101K . . . . . . . . . . . . . .R-197, R-222

P499RAP-102C . . . . . . . . . . . . . .R-197, R-222

P499RAP-105C . . . . . . . . . . . . . .R-197, R-222

P499RAP-105K . . . . . . . . . . . . . .R-197, R-222

P499RAP-107C . . . . . . . . . . . . . .R-197, R-222

P499RAP-107K . . . . . . . . . . . . . .R-197, R-222

P499RAPS100C . . . . . . . . . . . . . .R-197, R-222

P499RAPS100K . . . . . . . . . . . . . .R-197, R-222

P499RAPS102C . . . . . . . . . . . . . .R-197, R-222

P499RAPS102K . . . . . . . . . . . . . .R-197, R-222

P499RCP-101C . . . . . . . . . . . . . .R-197, R-221

P499RCP-101K . . . . . . . . . . . . . .R-197, R-221

P499RCP-105C . . . . . . . . . . . . . .R-197, R-221

P499RCP-105K . . . . . . . . . . . . . .R-197, R-221

P499RCP-107C . . . . . . . . . . . . . .R-197, R-221

P499RCP-107K . . . . . . . . . . . . . .R-197, R-221

P499RCP-401C . . . . . . . . . . . . . .R-197, R-221

P499RCP-402C . . . . . . . . . . . . . .R-197, R-221

Code Number Index

P499RCP-404C . . . . . . . . . . . . . R-197, R-221

P499RCP-405C . . . . . . . . . . . . . R-197, R-221

P499RCPS100C . . . . . . . . . . . . . R-197, R-221

P499RCPS100K . . . . . . . . . . . . . R-197, R-221

P499RCPS102C . . . . . . . . . . . . . R-197, R-221

P499RCPS102K . . . . . . . . . . . . . R-197, R-221

P545NCB-22C . . . . . . . . . . . . . . . . . . . . R-111

P545NCB-25C . . . . . . . . . . . . . . . . . . . . R-111

P545NCB-82C . . . . . . . . . . . . . . R-111, R-113

P67AA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-90

P67CA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-90

P67EA-5C . . . . . . . . . . . . . . . . . . . . . . . . . R-90

P70AA-118C . . . . . . . . . . . . . . . . . . . . . . . R-96

P70AA-119C . . . . . . . . . . . . . . . . . . . . . . . R-97

P70AA-2C . . . . . . . . . . . . . . . . . . . . . . . . . R-97

P70AA-400C . . . . . . . . . . . . . . . . . . . . . . . R-97

P70AA-5C . . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70AB-12C . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70AB-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70AB-2C . . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70BA-10C . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70BA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70CA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70CA-2C . . . . . . . . . . . . . . . . . . . . . . . . . R-96

P70CA-3C . . . . . . . . . . . . . . . . . . . . . . . . . R-96

P70CA-400C . . . . . . . . . . . . . . . . . . . . . . . R-97

P70CA-4C . . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70CA-5C . . . . . . . . . . . . . . . . . . . . . . . . . R-97

P70DA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-96

P70DA-2C . . . . . . . . . . . . . . . . . . . . . . . . . R-97

P70DA-400C . . . . . . . . . . . . . . . . . . . . . . . R-97

P70EA-10C . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70EA-14C . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70GA-11C . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70HA-3C . . . . . . . . . . . . . . . . . . . . . . . . . R-93

P70KA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-96

P70KA-7C . . . . . . . . . . . . . . . . . . . . . . . . . R-97

P70LA-2C . . . . . . . . . . . . . . . . . . . . . . . . R-101

P70LB-1C . . . . . . . . . . . . . . . . . . . . . . . . R-100

P70LB-6C . . . . . . . . . . . . . . . . . . . . . . . . R-100

P70MA-18C . . . . . . . . . . . . . . . . . . . . . . R-100

P70MA-1C . . . . . . . . . . . . . . . . . . . . . . . R-100

P70MA-2C . . . . . . . . . . . . . . . . . . . . . . . R-101

P70NA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-100

P70SA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-100

P72AA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-93

P72AA-27C . . . . . . . . . . . . . . . . . . . . . . . . R-96

P72AB-1C . . . . . . . . . . . . . . . . . . . . . . . . R-93

P72CA-2C . . . . . . . . . . . . . . . . . . . . . . . . R-96

P72DA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-96

P72LA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-100

P72LB-1C . . . . . . . . . . . . . . . . . . . . . . . . R-100

P72MA-1C . . . . . . . . . . . . . . . . . . . . . . . R-100

P72NA-1C . . . . . . . . . . . . . . . . . . . . . . . R-100

P74AA-1C . . . . . . . . . . . . . . . . . . . . . . . R-108

P74BA-1C . . . . . . . . . . . . . . . . . . . . . . . R-108

P74EA-10C . . . . . . . . . . . . . . . . . . . . . . R-108

P74EA-8C . . . . . . . . . . . . . . . . . . . . . . . R-108

P74FA-10C . . . . . . . . . . . . . . . . . . . . . . . R-108

P74FA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-108

P74FA-5C . . . . . . . . . . . . . . . . . . . . . . . . R-108

P74JA-2C . . . . . . . . . . . . . . . . . . . . . . . . R-108

PLT112-1 . . . . . . . . . . . . . . . . . . . . . . . . R-134

PLT112-2 . . . . . . . . . . . . . . . . . . . . . . . . R-134

PLT213-6R . . . . . . . . . . . . . . . . . . . . . . . . R-83

PLT231-1R . . . . . . . . . . . . . . . . . . . . . . . . R-83

PLT333-12R . . . . . . . . . . . . . . . . . . .R-72, R-83

PLT333-1R . . . . . . . . . . . . . . . . . . . .R-72, R-83

PLT333-2R . . . . . . . . . . . . . . . . . . . . . . . . R-83

PLT333-3R . . . . . . . . . . . . . . . . . . . .R-72, R-83

PLT333-4R . . . . . . . . . . . . . . . . . . . . . . . . R-83

PLT333-5R . . . . . . . . . . . . . . . . . . . .R-72, R-83

PLT344-1R . . . . . . . . . . . R-195, R-204, R-207,

. . . . . . . . . . . . . . . . . . . R-208, R-210, R-213,

. . . . . . . . . . . . . . . . . . . . R-214, R-216, R-218

R

R310AD-1C . . . . . . . . . . . . . . . . .R-112, R-122

R310AE-2C . . . . . . . . . . . . . . . . . . . . . . R-122

RLD-H10-100 . . . . . . . . . . . . . . . .R-125, R-126

RLD-H10-101 . . . . . . . . . . . . . . . . . . . . . R-125

RLD-H10-102 . . . . . . . . . . . . . . . . . . . . . R-125

RLD-H10-103 . . . . . . . . . . . . . . . . . . . . . R-125

RLD-H10-105 . . . . . . . . . . . . . . . . . . . . . R-125

RLD-H10-600R . . . . . . . . . . . . . . .R-125, R-126

RLD-H10-601R . . . . . . . . . . . . . . .R-125, R-126

RLD-H10-602R . . . . . . . . . . . . . . .R-125, R-126

RLD-H10-603R . . . . . . . . . . . . . . .R-125, R-126

RLD-H10-604R . . . . . . . . . . . . . . . . . . . . R-125

RLD-H10-606R . . . . . . . . . . . . . . .R-125, R-126

RLD-H10-607R . . . . . . . . . . . . . . .R-125, R-126

RLD-H10PM-1 . . . . . . . . . . . . . . . . . . . . R-125

RLD-H10PRO-1 . . . . . . . . . . . . . . . . . . . R-125

Code Number Index

RLY13A-600R . . . . . . . . . . . . . . . . . . . . . R-114

RLY13A-602R . . . . . . . . . . . . . . . . . . . . . R-114

RLY13A-608R . . . . . . . . . . . . . . . . . . . . . R-114

RLY13A-609R . . . . . . . . . . . . . . . . . . . . . R-114

RLY13A-610R . . . . . . . . . . . . . . . . . . . . . R-114

RLY13A-613R . . . . . . . . . . . . . . . . . . . . . R-114

RLY13A-616R . . . . . . . . . . . . . . . . . . . . . R-114

RLY13A-617R . . . . . . . . . . . . . . . . . . . . . R-114

ROD18A-600R . . . . . . . . . . . . . . . . . . . . R-147

ROD18A-601R . . . . . . . . . . . . . . . . . . . . R-147

ROD18A-602R . . . . . . . . . . . . . . . . . . . . R-147

ROD18A-603R . . . . . . . . . . . . . . R-147, R-148

ROD18A-604R . . . . . . . . . . . . . . . . . . . . R-147

RP4MRUHV-1C . . . . . . . . . . . . . . . . . . . . R-58

RP4MSUHV-1C . . . . . . . . . . . . . . . . . . . . R-78

S

S26AA-1 . . . . . . . . . . . . . . . . . . . . . . . . . . R-66

S26AH-1 . . . . . . . . . . . . . . . . . . . . . . . . . . R-66

S26DH-1 . . . . . . . . . . . . . . . . . . . . . . . . . . R-66

SCN10A-600R . . . . . . . . . . . . . . . . . . . . R-147

SCN10A-601R . . . . . . . . . . . . . . R-147, R-148

SEC37A-600R . . . . . . . . . . . . . . . . . . . . R-151

SEC37A-601R . . . . . . . . . . . . . . . . . . . . R-151

SEC37A-602R . . . . . . . . . . . . . . . . . . . . R-151

SEC99AA-18C . . . . . . . . . . . . . . . . . . . . R-124

SEC99AA-24C . . . . . . . . . . . . . . . . . . . . R-124 SEC99AA-36C . . . . . . . . R-124, R-151, R-152,

. . . . . . . . . . . . . . . . . . . . . . . . . R-154, R-160

SEC99AA-48C . . . . . . . . . . . . . . . . . . . . R-124

SEC99AA-60C . . . . . . . . . . . . . . . . . . . . R-124

SEC99AB-18C . . . . . . . . . . . . . . . . . . . . R-124

SEC99AB-24C . . . . . . . . . . . . . . . . . . . . R-124

SEC99AB-36C . . . . . . . . . . . . . . . . . . . . R-124

SEC99AB-48C . . . . . . . . . . . . . . . . . . . . R-124

SEC99AB-60C . . . . . . . . . . . . . . . . . . . . R-124

SEP107A-602R . . . . . . . . . . . . . . R-151, R-160

SEP127A-600R . . . . . . . . . . . . . . R-151, R-160

SEP13A-600R . . . . . . . . . . . . . . . . . . . . . R-152

SEP13A-602R . . . . . . . . . . . . . . . . . . . . . R-152

SEP13A-603R . . . . . . . . . . . . . . . . . . . . . R-152

SEP50A-600R . . . . . . . . . . . . . . . . . . . . . R-152

SEP50A-601R . . . . . . . . . . . . . . . . . . . . . R-152

SEP70A-601R . . . . . . . . . . . . . . . . . . . . . R-152

SEP70A-604R . . . . . . . . . . . . . . . . . . . . . R-152

SEP70A-605R . . . . . . . . . . . . . . . . . . . . . R-152

SEP77A-605R . . . . . . . . . . . . . . .R-151, R-160

SEP81A-601R . . . . . . . . . . . . . . .R-151, R-160

SEP81A-602R . . . . . . . . . . . . . . .R-151, R-160

SEP86A-600R . . . . . . . . . . . . . . . . . . . . R-147

SEP87A-600R . . . . . . . . . . . . . . . . . . . . R-147

SEP88A-600R . . . . . . . . . . . . . . .R-147, R-148

SEP88A-601R . . . . . . . . . . . . . . . . . . . . R-147

SEP91A-600R . . . . . . . . . R-151, R-152, R-154

SEP91A-601R . . . . . . . . . R-151, R-154, R-160

SEP91A-602R . . . . . . . . . R-151, R-154, R-160

SEP91A-603R . . . . . . . . . R-151, R-154, R-160

SET29A . . . . . . . . . . . . . . . . . . . . . . . . . R-157

SET29A-601R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-602R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-604R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-605R . . . . . . . . . . . . . . .R-157, R-159

SET29A-606R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-622R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-623R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-624R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-625R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-626R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-627R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-629R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-630R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-632R . . . . . . . . . . . . . . . . . . . . R-157

SET29A-633R . . . . . . . . . . . . . . . . . . . . R-157

SET98A-621R . . . . . . . . . . . . . . . . . . . . R-157

SHL10A-600R . . . . . . . . . . . . . . . . . . . . . R-79 SHL10A-603R . . . . . . . . . . R-79, R-196, R-220 STT14A . . . . . . . . . . . . . . . . . . . . . . . . . R-157 STT14A-600R . . . R-151, R-154, R-157, R-188 STT14A-601R . . . . . . . . . . . . . . .R-152, R-188

STT14A-603R . . . . . . . . . . . . . . . . . . . . R-152

STT15A . . . . . . . . . . . . . . . . . . . . . . . . . R-157 STT15A-602R . . . . . . . . R-151, R-154, R-157,

. . . . . . . . . . . . . . . . . . . . . . . . . .R-159, R-188 STT15A-603R . . . . . . . . . . . . . . .R-152, R-188

STT15A-605R . . . . . . . . . . . . . . .R-160, R-188

STT16A . . . . . . . . . . . . . . . . . . . . . . . . . R-157 STT16A-601R . . . . . . . . R-151, R-152, R-154,

. . . . . . . . . . . . . . . . . . . . R-157, R-159, R-188

STT16A-604R . . . . . . . . . . . . . . .R-160, R-188

STT17A . . . . . . . . . . . . . . . . . . . . . . . . . R-157

STT17A-604R . . . . . . . . . . . . . . .R-160, R-188

STT17A-609R . . . . . . . . R-151, R-152, R-154,

. . . . . . . . . . . . . . . . . . . . . . . . . .R-157, R-188

Code Number Index

T

T22AAA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T22ABC-1C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T22ABC-3C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T22BBC-1C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T22CBC-1C . . . . . . . . . . . . . . . . . . . . . . . R-68

T22CBC-3C . . . . . . . . . . . . . . . . . . . . . . . R-68

T22JAA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T22JCC-1C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T22SDA-1C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T22SEB-1C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T22SFB-1C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T22TFB-1C . . . . . . . . . . . . . . . . . . . . . . . . R-68

T23A-1C . . . . . . . . . . . . . . . . . . . . . . . . . . R-70

T23B-1C . . . . . . . . . . . . . . . . . . . . . . . . . . R-70

T25A-16C . . . . . . . . . . . . . . . . . . . . . . . . . R-68

T25A-1C . . . . . . . . . . . . . . . . . . . . . . . . . . R-68

T26A-14C . . . . . . . . . . . . . . . . . . . . . . . . . R-68

T26A-15C . . . . . . . . . . . . . . . . . . . . . . . . . R-68

T26J-7C . . . . . . . . . . . . . . . . . . . . . . . . . . R-68

T26J-9C . . . . . . . . . . . . . . . . . . . . . . . . . . R-68

T26S-18C . . . . . . . . . . . . . . . . . . . . . . . . . R-68

T26T-3C . . . . . . . . . . . . . . . . . . . . . . . . . . R-68

T28BD-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-71

T28CD-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-71

T28DA-1C . . . . . . . . . . . . . . . . . . . . . . . . . R-71

TE-6000-x . . . . . . . . . . . . . . . . . . .R-196, R-220

TE-6001-1 . . . . . . . . . . . . . . . . . .R-196, R-220

TE-6001-11 . . . . . . . . . . . . . . . . .R-196, R-220

TE-631xx-x . . . . . . . . . . . . . . . . . .R-196, R-220

TE-68NT-0N00S . . . . . . . . . . . . . .R-196, R-221

V

V248GB1-001C . . . . . . . . . . . . . . . . . . . R-181

V248GB1B001C . . . . . . . . . . . . . . . . . . . R-181

V248GC1-001C . . . . . . . . . . . . . . . . . . . R-181

V248GC1B001C . . . . . . . . . . . . . . . . . . . R-181

V248GD1-001C . . . . . . . . . . . . . . . . . . . R-181

V248GD1B001C . . . . . . . . . . . . . . . . . . . R-181

V248GE1-001C . . . . . . . . . . . . . . . . . . . R-181

V248GE1B001C . . . . . . . . . . . . . . . . . . . R-181

V248GF1-001C . . . . . . . . . . . . . . . . . . . R-181

V248GF1B001C . . . . . . . . . . . . . . . . . . . R-181

V248GK1-001C . . . . . . . . . . . . . . . . . . . R-181

V248GL1-001C . . . . . . . . . . . . . . . . . . . R-181

V248GM1-001C . . . . . . . . . . . . . . . . . . . R-181

V248HC1B001C . . . . . . . . . . . . . . . . . . . R-181

V43AS-1C . . . . . . . . . . . . . . . . . .R-145, R-147

V43AS-2C . . . . . . . . . . . . . . . . . .R-145, R-147

V43AS-5C . . . . . . . . . . . . . . . . . . . . . . . R-147

V43AT-1C . . . . . . . . . . . . . . . . . . .R-145, R-147

V43AT-2C . . . . . . . . . . . . . . . . . . .R-145, R-147

Code Number Index

Code Number Index

V47AA-2C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AA-3C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AB-27C . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AB-2C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AB-3C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AB-4C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AB-5C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AC-3C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AC-40C . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AC-4C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AC-6C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AC-8C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AD-19C . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AD-1C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AD-2C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AD-3C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AE-13C . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AE-1C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AE-2C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AE-3C . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AR-1 . . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AR-2 . . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AR-3 . . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AS-1 . . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AS-13C . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AS-2 . . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AS-3 . . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AT-1 . . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AT-2 . . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47AT-3 . . . . . . . . . . . . . . . . . . . . . . . . . R-157

V47NB-1C . . . . . . . . . . . . . . . . . . . . . . . . R-159

V47NC-1C . . . . . . . . . . . . . . . . . . . . . . . . R-159

V47NR-1C . . . . . . . . . . . . . . . . . . . . . . . . R-159

V48AB-1C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AB-2C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AC-1C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AC-2C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AD-1C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AD-2C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AE-1C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AE-2C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AF-1C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AF-2C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AJ-2C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AL-2C . . . . . . . . . . . . . . . . . . . . . . . . R-160

V48AM-2C . . . . . . . . . . . . . . . . . . . . . . . R-160

V48EK-2C . . . . . . . . . . . . . . . . . . . . . . . . R-160

VFD68BBB-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68BCB-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68BDC-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68BFD-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68BGG-2C . . . . . . . . . . . . . . . . . . . R-143

VFD68BHG-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68BJK-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68BKL-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68BLL-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68BMP-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68BNP-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68CDF-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68CFF-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68CGG-2C . . . . . . . . . . . . . . . . . . . R-143

VFD68CHH-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68CJJ-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68CKL-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68CLL-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68CMP-2C . . . . . . . . . . . . . . . . . . . R-143

VFD68CNP-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68DFM-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68DGM-2C . . . . . . . . . . . . . . . . . . . R-143

VFD68DHM-2C . . . . . . . . . . . . . . . . . . . R-143

VFD68DJN-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68DKN-2C . . . . . . . . . . . . . . . . . . . . R-143

VFD68DLN-2C . . . . . . . . . . . . . . . . . . . . R-143

W

WEL11A-601R . . . . . . . . . . . R-33, R-36, R-79,

. . . . . . . . . . . . . . . . . . . . . R-80, R-196, R-220

WEL14A-601R . . . . . . . . . . . . . . . . . . . . . R-80 WEL14A-602R . . . . . . R-19, R-21, R-25, R-37,

. . . . . . . . . . . . . . . . . . . . . . . R-59, R-65, R-80 WEL14A-603R . . R-19, R-25, R-59, R-65, R-80

WEL16A-600R . . . . . . . R-25, R-35, R-62, R-80

WEL16A-601R . . . . . . . . . . . . . . . . .R-19, R-80

WEL17A-600R . . . . . . . . . . . . . . . .R-80, R-157

WEL17A-601R . . . . . . . . . . . . . . . .R-80, R-157

WEL17A-602R . . . . . . . . . . . . . . . . . . . . . R-80

WEL17A-604R . . . . . . . . . . . . . . . . . . . . . R-80

WEL18A-600R . . . . . . . . . . . . . . . . . . . . . R-80

WEL18A-601R . . . . . . . . . . . . . . . . . . . . R-159

WEL18A-602R . . . . . . . . . . R-80, R-157, R-159

WGT11A-600R . . . . . . . . . . . . . . . . . . . . R-127

WGT11A-604R . . . . . . . . . . . . . . . . . . . . R-127

Code Number Index

Y

Y63F22-0 . . . . . . . . . . . . . . . . . . . . . . . . R-190

Y63T22-0 . . . . . . . . . . . . . . . . . . . . . . . . R-190

Y66T12-0 . . . . . . . . . . . . . . . . . . . . . . . . R-191

Y66T13-0 . . . . . . . . . . . . . . . . . . . . . . . . R-191

Y69T15-0 . . . . . . . . . . . . . . . . . . . . . . . . R-191

| Single-Stage Electromechanical Temperature Controls Code No. LIT-1927005 |

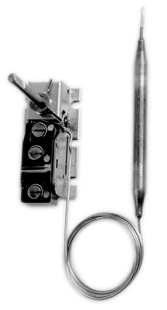

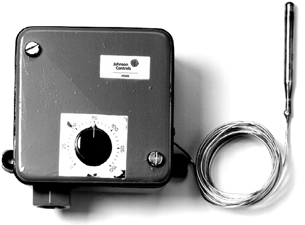

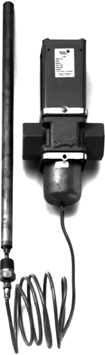

![]() A11 Series Low Temperature Cutout Controls

A11 Series Low Temperature Cutout Controls

![]()

![]()

![]()

Description

A11 Series Low Temperature Cutout Controls are available with single-pole, single-throw (SPST) or single-pole, double-throw (SPDT) contact action. Typical applications include the sensing of low temperature conditions to avoid over cooling or icing of hydronic coils, cooling coils, and liquid-handing pipes. The controls are compact and sturdy, and have an adjustable temperature setpoint range with a fixed differential. The range adjustment screw is accessible at the bottom of the control, and at the top of the control when the cover is removed.

The A11 Controls are compact and sturdy and feature an adjustable range with a fixed differential. The range adjustment screw is accessible at the bottom of the control or at the top, when the cover is removed. A factory-set low temperature stop is available when specified.

Refer to the A11 Series Low Temperature Cutout Controls Product Bulletin (LIT-125010) for important product application information.

Electrical Rating

| Motor Rating | 120 V | 208 V | 240 V |

| Motor Description | |||

| AC Full Load Amperes | 16.0 | 9.2 | 8.0 |

| AC Locked Rotor Amperes | 96.0 | 55.2 | 48.0 |

| Non-Inductive Amperes | 16.0 | 9.2 | 8.0 |

| Pilot Duty | 125 VA, 24 to 277 VAC | ||

Selection Chart

Features

- precision repeat accuracy remains unaffected by ambient temperature at the control diaphragm cup and 4 ft (1.2 m) capillary (20 ft [6.1 m] sensing bulb must be in the controlled area)

- trip-free manual reset allows the lever to reset. You must press and release the lever before operation resumes.

- precision snap-acting contacts in a dust protected enclosure enables the A11 Control to operate to the fullest potential

- direct reading scale provides

easy-to-adjust setpoint. Adjustments can be made from the top or bottom of the control.

Repair Information

If the A11 Series Low Temperature Cutout Control fails to operate within its specifications, replace the unit. For a replacement control, contact the nearest Johnson Controls® representative.

A11 Series Low Temperature Cutout Control

| Model | Description |

| A11A | SPST, open low, manual reset |

| A11B | SPST, open low, automatic recycle |

| A11D | SPDT, manual reset |

| A11E | SPDT, automatic recycle |

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

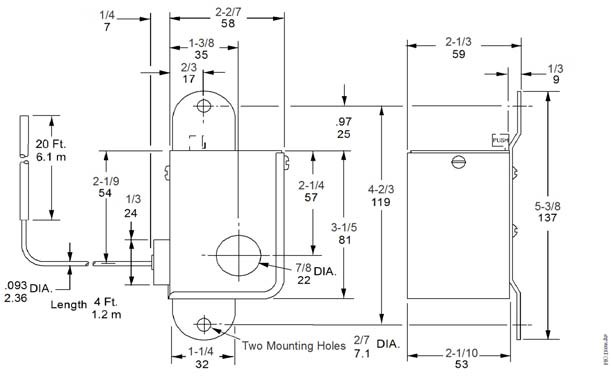

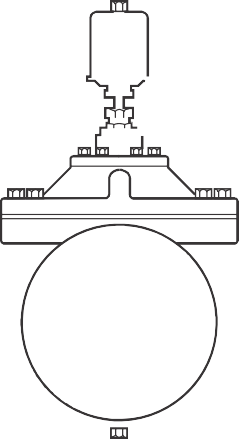

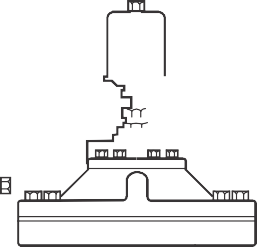

A11 Series Low Temperature Cutout Controls Dimensions, in. (mm)

| Single-Stage Electromechanical Temperature Controls |

A11 Series Low Temperature Cutout Controls (Continued)

![]()

![]()

![]()

![]()

Technical Specifications

| A11 Low Temperature Cutout Controls | ||

| Product Codes | A11A: SPST, open low, manual reset

A11B: SPST, open low, automatic recycle A11D: SPDT, manual reset A11E: SPDT, automatic recycle |

|

| Range Cutout | 35 to 45°F (2 to 7°C) | |

| Differential | A11A and A11D: Temperature must be 12°F (6.7°C) above cutout point before control can be reset. A11B and A11E: 12°F (6.7°C) | |

| Ambient Temperature | Minimum: 0°F (-18°C) Maximum: 140°F (60°C) | |

| Maximum Temperature at Bulb | 250°F (121°C) | |

| Sensing Element | 1/8 in. x 20 ft (3 mm x 6.1 m) or 1/8 in. x 40 ft (3 mm x 12.2 m) | |

| Capillary Length | 4 ft (1.2 m) | |

| Switch | Snap-acting contacts in dust-protected enclosure | |

| Material | Case: 0.6 (2 mm) cold rolled steel Cover: 0.3 in. (1 mm) cold rolled steel | |

| Finish | Galvanized steel | |

| Conduit Opening | 22 mm (9/10 in.) hole for 13 mm (1/2 in.) conduit | |

| Mounting Bracket | Standard on all controls | |

| Shipping Weight | Individual pack: 1.8 lb (0.8 kg)

Overpack of 20 units: 38 lb (17 kg) |

|

| Electrical Rating | Pilot Duty: 125 VA, 24 to 277 VAC | |

| Motor Ratings | AC Full Load Ampere: 120 V = 16.0 A, 208 V = 9.2 A, 240 V = 8.0 A

AC Locked Rotor Ampere: 120 V = 96.0 A, 208 V = 55.2 A, 240 V = 48.0 A Non-Inductive Ampere: 120 V = 16.0 A, 208 V = 9.2 A, 240 V = 8.0 A |

|

| Compliance | United States | UL Listed, File SA516, SDFY |

| FCC Compliant to CFR 47, Part 15 Subpart B, Class A | ||

| Canada | UL Listed, CSA Class No. 1222 01, File LR948 | |

| Industry Canada, ICES-003 | ||

Single-Stage Electromechanical Temperature Controls Code No. LIT-1927010

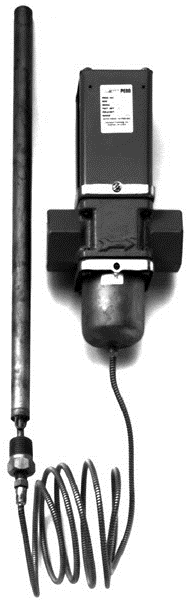

![]() A19 Series Remote Bulb Control

A19 Series Remote Bulb Control

![]()

![]()

![]()

Description

The A19 Series Controls are single-stage temperature controls that incorporate environmentally friendly liquid-filled sensing elements.

Refer to the A19 Series Hot Water Heating Controls Well Immersion Product Bulletin (LIT-125025) for important product application information.

Features

- wide temperature ranges available

- constant differential throughout the entire range

- compact enclosure

- fixed or adjustable differential available

- variety of sensing element styles

- unaffected by cross-ambient conditions

Applications

The A19 is suitable for temperature control in HVAC/R applications.

Selection Charts

A19 Series Remote Bulb Control1

A19 Series

![]()

Y

R

B

Action on Increase of Temperature

![]()

![]()

![]()

a19.eps

A19 Series

Terminal Arrangement for Single-Pole, Double-Throw (SPDT)

A19ABC-24 Remote Bulb Control

- Specify the control model code number, packing nut code number (if required), and bulb well code number (if required).

- Replaces White-Rodgers® 1609-101

3. Replaces White-Rodgers 1609-12, -13; Ranco® 010-1408, -1409, – 1410, -1490, 060-110; Honeywell® L6018C-1006, L6021A-1005, T675A-1011, -1508, -1516,

-1821, T4301A-1008, T6031A-1011, T6031A-1029

4. Case-Compensated

| Single-Stage Electromechanical Temperature Controls |

A19 Series Remote Bulb Control (Continued)

![]()

![]()

![]()

![]()

Replacement Parts

| Product Code Number | Description |

| CVR28A-617R | Concealed adjustment cover |

| CVR28A-618R | Visible scale cover |

| KNB20A-602R | Replacement Knob Kit |

Accessories

A packing nut is available for closed tank application. Specify the code number FTG13A-600R.

Bulb wells (WEL14A Series) are available for liquid immersion applications. See the selection chart or the Bulb Wells Catalog Page (LIT-1922135).

Technical Specifications

Electrical Ratings

| Motor Ratings VAC | 120 | 208 | 240 |

| Wide Range – Adjustable Differential | |||

| AC Full Load A | 16.0 | 9.2 | 8.0 |

| AC Locked Rotor A | 96.0 | 55.2 | 48.0 |

| Non-Inductive A1 | 22 A, 120 to 277 VAC | ||

| Pilot Duty | 125 VA, 24 to 600 VAC | ||

| Fixed Differential and Close Differential | |||

| AC Full Load A | 6.0 | 3.4 | 3.0 |

| AC Locked Rotor A | 36.0 | 20.4 | 18.0 |

| Non-Inductive A | 10 A, 24 to 277 VAC | ||

| Pilot Duty | 125 VA, 24 to 277 VAC | ||

| Case Compensated – Fixed Differential A19AAC-4 | |||

| AC Full Load A | 16.0 | 9.2 | 8.0 |

| AC Locked Rotor A | 96.0 | 55.2 | 48.0 |

| Non-Inductive A1 | 22 A, 120 to 277 VAC | ||

| Pilot Duty | 125 VA, 24 to 600 VAC | ||

| A19AAD-12 | |||

| AC Full Load A | 6.0 | 3.4 | 3.0 |

| AC Locked Rotor A | 36.0 | 20.4 | 18.0 |

| Non-Inductive A | 10 A, 24 to 277 VAC | ||

| Pilot Duty | 125 VA, 24 to 277 VAC | ||

| Manual Reset | |||

| AC Full Load A | 16.0 | 9.2 | 8.0 |

| AC Locked Rotor A | 96.0 | 55.2 | 48.0 |

| Non-Inductive A | 16.0 | 9.2 | 8.0 |

| Pilot Duty | 125 VA, 24 to 600 VAC | ||

1. SPST and N.O. contact of SPDT control;

SPDT N.C. contact- 16 amperes 120 to 277 VAC

Single-Stage Electromechanical Temperature Controls Code No. LIT-1927015

A19 Series High Range Temperature Control

A19 Series High Range Temperature Control

![]()

![]()

![]()

Description

The A19 Series Controls are single-stage temperature controls that incorporate liquid-filled sensing elements.

Refer to the A19 Series Hot Water Heating Controls Well Immersion Product Bulletin (LIT-125025) for important product application information.

Features

- wide temperature ranges available

- constant differential throughout the entire range

- single-pole, single-throw (SPST) or single-pole, double-throw (SPDT) snap-acting switches

- fixed or adjustable differential available

- unaffected by barometric pressure changes

- unaffected by cross-ambient conditions

- compact enclosure

- variety of sensing element styles

Applications

The A19s are suitable for temperature control in HVAC/R applications.

Selection Charts

A19 Series High Range Temperature Control

A19 Series

![]()

Y

R

B

Action on Increase of Temperature

![]()

![]()

![]()

a19.eps

A19 Series

Terminal Arrangement for SPDT

A19AAB Temperature Control

| Product Code | Switch

Action |

Range

°F (°C) |

Diff F° (C°)

(Factory Set) |

Bulb and

Capillary |

Bulb Well No. | Range

Adjuster |

Max Bulb

Temp °F (°C) |

| A19AAB-4C | SPST, open high | 30 to 110

(-1 to 43) |

3-1/2 (1.9) | 3/8 in. x 5 in.

copper 6 ft. capillary2 |

WEL14A-602R | Screwdriver slot

Visible scale |

140 (60) |

| A19AAB-7C | SPST, open high Oven Thermostat | 100 to 300

(38 to 149) |

7 (3.9) | 3/16 in. x 9-1/2 in. copper 6 ft. capillary | – | Knob Visible scale | 350 (177) |

| A19AAB-10C | SPST, open high Oven Thermostat | 200 to 550

(93 to 288) |

10 (5.6) | 3/16 in. x 6 in. copper 8 ft. capillary | – | Convertible | 620 (327) |

| A19AAC-9C | SPDT | 100 to 240 | 6 (3.3) | 3/8 in. x 3-1/2 in. copper 6 ft. capillary2 | WEL14A-602R | Screwdriver slot Visible Scale | 290 (143) |

| A19ABB-2C | SPST, open high Remote Bulb Thermostat | 50 to 200

(10 to 93) |

Adjustable 6 to 24

(3 to 13) |

0.290 in. x 2-1/2 in. copper 10 ft. capillary | – | Knob

Visible Scale |

240 (116) |

| A19ABB-7C | 50 to 201

(10 to 94) |

7 x 64 mm | 240 (116) |

- Specify code number, and closed tank fitting (Code Number FTG13A-600R), or bulb well, if required.

- With 3-inch bulb support

Replacement Parts

| Product Code Number | Description |

| CVR28A-617R | Concealed adjustment cover |

| CVR28A-618R | Visible scale cover |

| KNB20A-602R | Replacement knob kit |

Technical Specifications

Electrical Ratings

| Motor Ratings VAC | 120 | 208 | 240 |

| AC Full Load A | 16.0 | 9.2 | 8.0 |

| AC Locked Rotor A | 96.0 | 55.2 | 48.0 |

| Non-Inductive A1 | 22 A, 120 to 277 VAC | ||

| Pilot Duty | 125 VA, 24 to 600 VAC | ||

1. SPST and N.O. contact of SPDT control SPDT N.C. contact – 16 A, 120 to 277 VAC

| Single-Stage Electromechanical Temperature Controls Code No. LIT-1927020 |

A19 Series Thermostat for Crop Drying

A19 Series Thermostat for Crop Drying

![]()

![]()

![]()

Description

The A19 Series are single-stage temperature controls that incorporate liquid-filled sensing elements.

Refer to the A19 Series Utility Thermostats for Farm, Industrial, and Commercial Use Product Bulletin (LIT-125030) for important product application information.

Technical Specifications

The maximum bulb temperature for the A19AAE-3 is 200°F (93°C) and for the A19ABB-2 is 240°F (116°C).

Electrical Rating 120 VAC

| Motor Ratings VAC | 120 | 208 | 240 |

| A19AAE-3 | |||

| AC Full Load A | 6.0 | 3.4 | 3.0 |

| AC Locked Rotor A | 36.0 | 20.4 | 18.0 |

| Non-Inductive or Resistance Load A (Not Lamp Loads) | 10 A

120 to 277 VAC |

||

| Pilot Duty | 125 VA,

24 to 277 VAC |

||

| A19ABB-2 | |||

| AC Full Load A | 10.0 | – | 6.0 |

| AC Locked Rotor A | 60.0 | – | 36.0 |

| Pilot Duty | 125 VA,

24 to 600 VAC |

||

Features

- designed for high temperature applications

- narrow (2F° fixed) or wide adjustable differentials

Applications

Crop drying thermostat energizes gas valve to maintain temperature.

Repair Information

If the A19 Series Thermostat for Crop Drying fails to operate within its specifications, replace the unit. For a replacement thermostat, contact the nearest Johnson Controls® representative.

Selection Chart

A19AAE-3 Thermostat

| Product | Switch

Action |

Range

°F (°C) |

Differential

F°(C°) |

Bulb and

Capillary |

Range

Adjuster |

Max. Bulb

Temperature °F (°C) |

| A19AAE-3C | Single-Pole, | 80 to 180

(27 to 82) |

2 (1.1) fixed | 1/8 in. x 1-1/4 in.

copper-coiled 10 ft capillary |

Knob

Ext. scale |

200 (93) |

| A19ABB-2C | SPST open high | 50 to 200

(10 to 93) |

6 to 24

(3 to 13) adjustable |

0.290 in. x 2-1/2 in.

10 ft. capillary |

Knob

Ext. Scale |

240 (116) |

| Single-Stage Electromechanical Temperature Controls Code No. LIT-1927030 |

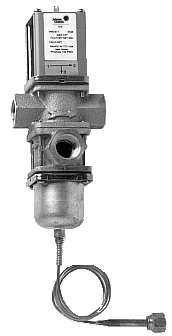

![]() A19 Series Hot Water Temperature Control (Well Immersion)

A19 Series Hot Water Temperature Control (Well Immersion)

![]()

![]()

![]()

Description

The A19 Series Temperature Controls are a universal replacement control for open high or single-pole, double-throw (SPDT) applications. The control is furnished with a well assembly for 1/2 in. tapping.

Refer to the A19 Series Hot Water Heating Controls Well Immersion Product Bulletin (LIT-125025) for important product application information.

Features

- liquid-filled element provides rapid response to temperature change

- adjustable differential

- universal replacement

Applications

This operating control is ideal for hot water boilers.

Selection Charts

A19 Series Hot Water Temperature Control (Well Immersion)

A19ABC-11

A19ABC-11

Temperature Control

A19ABC-12 Temperature Control

Replacement Parts

| Product Code Number | Description |

| CVR28A-617R | Concealed adjustment cover |

| CVR28A-618R | Visible scale cover |

| KNB20A-602R | Knob kit |

Technical Specifications

Electrical Ratings

| Motor Ratings VAC | 120 | 240 |

| AC Full Load A | 10.0 | 6.0 |

| AC Locked Rotor A | 60.0 | 36.0 |

| Pilot Duty | 125 VA, 24 to 600 VAC | |

Single-Stage Electromechanical Temperature Controls Code No. LIT-1927035

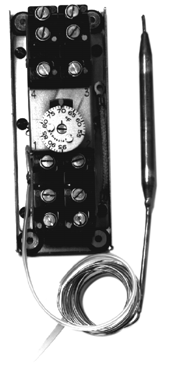

A19 Temperature Control Less Enclosure (SPDT, Close Differential)

A19 Temperature Control Less Enclosure (SPDT, Close Differential)

![]()

![]()

![]()

Description

The A19 Temperature Control Less Enclosure is an open-type temperature control for mounting in cases or enclosures.

Refer to the A19 Series Temperature Controls Less Enclosure Product Bulletin (LIT-125045) for important product application information.

Features

This control is designed with single-pole, double-throw (SPDT) contacts for open high or open low applications.

Applications

Use for panel-mounted temperature control for a packaged terminal air conditioner or for

self-contained HVAC equipment.

Selection Charts

A19 Series

![]()

Y

R

B

Action on Increase of Temperature

![]()

![]()

![]()

a19.eps

A19 Series

Terminal Arrangement for SPDT

A19AGF-31 Temperature Control

A19 Temperature Control Less Enclosure (SPDT, Close Differential) Replacement Parts

Technical Specifications Electrical Ratings

| Motor Ratings VAC | 120 | 208 | 240 |

| AC Full Load A | 6.0 | 3.4 | 3.0 |

| AC Locked Rotor A | 36.0 | 20.4 | 18 |

| Non-Inductive | 10 A, 120 to 277 VAC | ||

| Pilot Duty | 125 VA, 24 to 277 VAC | ||

- back mounting

- knob supplied by the customer

| Single-Stage Electromechanical Temperature Controls Code No. LIT-1927045 |

![]() A19 Series Thermostat for Hazardous Locations

A19 Series Thermostat for Hazardous Locations

![]()

![]()

![]()

Description

The A19 Series Thermostat provides remote bulb or coiled bulb sensing for hazardous environments.

Refer to the Types A19AUC, A19BUC Fixed Differential Thermostat For Hazardous Location Product Bulletin (LIT-121035) for important product application information.

Features

- precision enclosed switch and a liquid-filled sensing element provides repeat accuracy that is unaffected by barometric pressure and cross-ambient temperature fluctuations

- single-pole, double-throw (SPDT) switch provides open high or close high action for heating or cooling

- electrical rating permits direct control of most equipment

Selection Chart

Applications

These thermostats are designed for use in grain elevators, chemical and powder plants, mines, oil refineries, and similar sites. For use in Class I, Group D and Class II, Groups E, F, and G hazardous locations.

Repair Information

If the A19 Series Thermostat for Hazardous Locations fails to operate within its specifications, replace the unit. For a replacement thermostat, contact the nearest Johnson Controls® representative.

Technical Specifications

Electrical Ratings

| Motor Ratings VAC | 120 | 208 | 240 | 277 |

| Full Load Amperes | 16.0 | 9.2 | 8.0 | – |

| Locked Rotor Amperes | 96.0 | 55.2 | 48.0 | – |

| Non-Inductive Amperes | 22.0 | 22.0 | 22.0 | 22.0 |

| Pilot Duty | 125 VA, 24 to 600 VAC | |||

A19AUC

Thermostat

A19BUC

Thermostat

Single-Stage Electromechanical Temperature Controls Code No. LIT-1927050

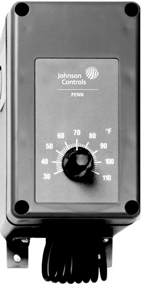

A19 Series Coiled Bulb Space Thermostat

A19 Series Coiled Bulb Space Thermostat

![]()

![]()

![]()

Description

The A19 Series Thermostat is a wide range temperature control with air coil sensing element.

Refer to the A19 Series Utility Thermostats for Farm, Industrial, and Commercial Use Product Bulletin (LIT-125030) for important product application information.

Features

- wide temperature range

- NEMA 1 enclosure

Applications

Use for return air or space temperature sensing.

Selection Charts

A19 Series Coiled Bulb Space Thermostat

A19 Series

![]()

Y

R

B

Action on Increase of Temperature

![]()

![]()

![]()

a19.eps

A19 Series

Terminal Arrangement for SPDT

A19BAC Thermostat

Technical Specifications

Electrical Ratings

| Motor Ratings VAC | 120 | 208 | 240 |

| A19BAB, A19BAC | |||

| AC Full Load A | 16.0 | 9.2 | 8.0 |

| AC Locked Rotor A | 96.0 | 55.2 | 48.0 |

| Non-Inductive or Resistance Load A1 (Not Lamp Loads) | 22 A,

120 to 277 VAC |

||

| Pilot Duty | 125 VA,

24 to 600 VAC |

||

| A19BAF | |||

| AC Full Load A | 6.0 | 3.4 | 3.0 |

| AC Locked Rotor A | 36.0 | 20.4 | 18.0 |

| Non-Inductive or Resistance Load A (Not Lamp Loads) | 10 A,

120 to 277 VAC |

||

| Pilot Duty | 125 VA,

24 to 277 VAC |

||

| Cooling – A19BBC | |||

| AC Full Load A | 16.0 | 9.2 | 8.0 |

| AC Locked Rotor A | 96.0 | 55.2 | 48.0 |

| Non-Inductive or Resistance Load A1 (Not Lamp Loads) | 22 A,

120 to 277 VAC |

||

| Pilot Duty | 125 VA,

24 to 600 VAC |

||

1. Replaces White-Rodgers® 201-16, -8, 2A37-1; Ranco® 010-1418, -1802, 016-594, C30-C1101; Honeywell® T631A, T696A, T6054 A1005.

Replacement Parts

| Product Code Number | Description |

| CVR28A-617R | Concealed adjustment cover |

| CVR28A-618R | Visible scale cover |

| KNB20A-602R | Knob kit |

1. SPST and only one side of SPDT control; SPDT – 16 A 120 to 277 VAC

| Single-Stage Electromechanical Temperature Controls Code No. LIT-1927055 |

![]()

Description

A19 Thermostat for Portable Heaters (Chain Mount and Drop Cord Electrical Connection)

Applications

![]()

![]()

![]()

The A19 Series Thermostat is a sturdy compact thermostat designed especially for temporary installations.

Refer to the Type A19BAG Thermostat for Portable Heaters with Thermostat Extension Cord and Beaded Chain Hanger Product Bulletin (LIT-121040) for important product application information.

Features

- 6-foot extension cord with piggyback style plug

- NEMA 1 enclosure

- chain mount

Selection Chart

- on/off control of portable space heaters

- agriculture

Repair Information

If the A19 Thermostat for Portable Heater fails to operate within its specifications, replace the unit. For a replacement thermostat, contact the nearest Johnson Controls® representative.

Technical Specifications

Electrical Ratings

| Motor Ratings VAC | 120 |

| AC Full Load A | 15 |

| AC Locked Rotor A | 90 |

A19BAG-1 Thermostat

| Product Code | Switch Action | Range

°F (°C) |

Differential

F° (C°) |

Maximum Bulb

Temperature °F (°C) |

| A19BAG-1C | Single-Pole,

Single-Throw (SPST) open high No-Heat position |

35 to 95

(2 to 35) |

3 (1.7)

Non-adjustable |

140 (60) |

| Single-Stage Electromechanical Temperature Controls Code No. LIT-1900402 |

![]() A19 Thermostat for Portable Cooling Applications (Chain Mount and Drop Cord Electrical Connection)

A19 Thermostat for Portable Cooling Applications (Chain Mount and Drop Cord Electrical Connection)

![]()

![]()

![]()

Description

The A19 Series Thermostat is a sturdy compact thermostat designed especially for temporary installations.

Refer to the A19 Series Hot Water Heating Controls Well Immersion Product Bulletin (LIT-125025) for important product application information.

Features

- 6-foot extension cord with piggyback style plug

- NEMA 1 enclosure

- chain mount

- remote sensing bulb with 6 ft (1.8 m) capillary tube

Selection Chart

Applications

- on/off control of portable cooling applications

- home brewing

Repair Information