REFRIGERATOR SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Model #s:

Model #s:

P/No. MFL62188020

795.71052.01, 795.71053.01, 795.71054.01

- SPECIFICATIONS 3-4

- PARTS IDENTIFICATION 5

-

REMOVING AND REPLACING REFRIGERATOR DOORS 6

DOOR 7

DOOR ALIGNMENT 8

FAN AND FAN MOTOR (EVAPORATOR) 8

DEFROST CONTROL ASSEMBLY 8

LAMP 9

MULTI DUCT 9

DISPENSER 10

DISPLAY PWB REPLACEMENT 10

FUNNEL REPLACEMENT 10

SUB PWB FOR DISPENSER 10

CAP DUCT REPLACEMENT 11

CAP DUCT MOTOR REPLACEMENT 11

ICE CORNER DOOR REPLACEMENT 11

ICE MAKER REPLACEMENT 12

HOW TO REMOVE A ICE BIN 13

HOW TO INSERT A ICE BIN 13

HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER 14-15

WATER VALVE DISASSEMBLY METHOD 16

FAN AND FAN MOTOR DISASSEMBLY METHOD 16

PULL OUT DRAWER 17

-

ADJUSTMENT 18-19

INTRODUCTION OF E-LINEAR COMPRESSOR 18-20

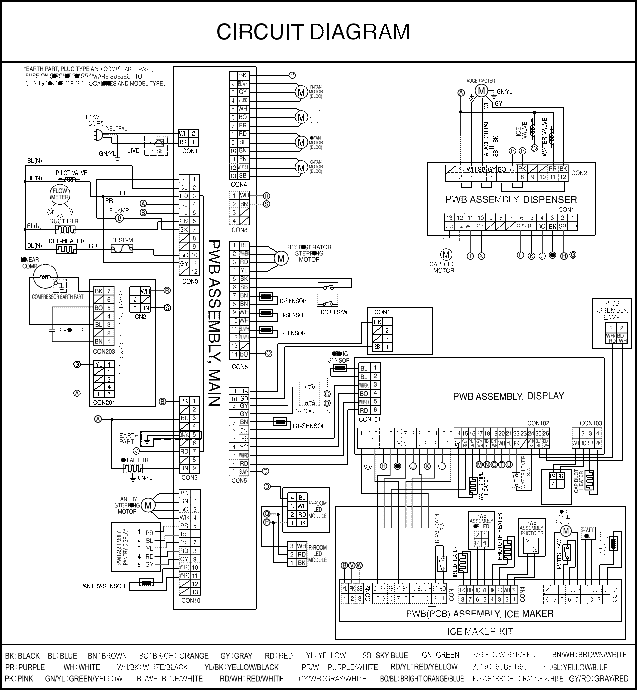

- CIRCUIT DIAGRAM 21

- TROUBLESHOOTINTG 22

- PCB PICTURE 23-24

- TROUBLESHOOTING WITH ERROR DISPLAY 25-34

- TROUBLESHOOTING WITH ERROR DISPLAY 35-44

- REFERENCE 44-49

- COMPONENT TESTING INFORMATION 50-54

- TRBOUBLESHOOTING 55-61

- ICEMAKER OPERATING METHOD AND TROUBLE SHOOTING 62-65

- DESCIPTION OF FUNCTION & CIRCUIT OF MICOM 66-69

SAFETY PRECAUTIONS

Please read the following instructions before servicing your refrigerator.

- Unplug the power before handling any electrical components.

- Check the rated current, voltage, and capacity.

- Take caution not to get water near any electrical components.

- Use exact replacement parts.

- Remove any objects from the top prior to tilting the product.

1-1 DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT – RECONNECT ALL GROUNDING DEVICES

All parts of this appliance capable of conducting electrical

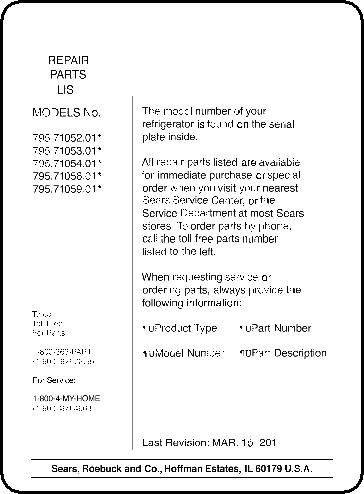

1-7 REPLACEMENT PARTS

28cu,ft 795.71052.01*

795.71053.01*

795.71054.01*

795.71056.01*

795.71059.01*

current are grounded. If grounding wires, screws, straps, clips, nuts or washers used to complete a path to ground are removed for service, they must be returned to their original position and properly fastened.

-

IMPORTANT NOTICE

This information is intended for use by individuals possessing adequate backgrounds of electrical, electronic and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property damage. The manufacturer or seller cannot be responsible for the interpretation of this information, nor can it assume any liability in connection with its use.

-

ELECTRICAL SPECIFICATIONS

Temperature Control (Freezer Compartment) . -6°F to +8°F Defrost Control ……Total Comp Running Time: 7 hrs~50 hrs Defrost Thermostat ……………………………………………… 46°F Electrical Rating : 115VAC, 60Hz ………………………….. 5.2 A

Maximum Current Leakage ……………………………….. 0.5 mA

Maximum Ground Path Resistance ………………. 0.14 Ohms

Energy Consumption …………………… 28cu,ft. 528 (E/STAR)

Defrost Thermostat ………………………………… 6615JB2005H

Defrost Heater ……………………………………….. 5300JK1005D

Evaporator Fan Motor …………………………….. 4681JB1027C

Capacitor (Running) ………………………………. EAE58905701

Compressor (Hi-Side) …………………………….. TCA34649901

Evaporator (Lo-Side) ……………………………….. 5421JJ1003L

Condenser …………………………………………… ACG72915205

Dryer ……………………………………………………. 5851JA2007E Condenser Fan Motor ……………………………. .4681JB1029D

Temperature Control …………………….. ACQ76217902(STS)

ACQ76217904(WB) ACQ76217906(SW) ACQ76217907(TI) ACQ76217908(BI)

Main Control …………………………………………. EBR65002702

Ice Fan Motor ………………………………………… 4681JB1027E

(4681JB1029E) Refrigerator Fan Motor ………………………………4681JB1027J

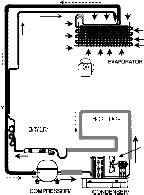

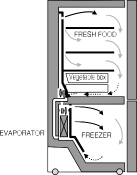

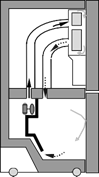

1-8 AIR FLOW / CIRCULATION D’AIR

- NO LOAD PERFORMANCE CONTROL POSITION: MID/MID

And Ambient of : ……………. 70°F …………………………… 90°F Fresh Food, °F ……………… 33°F to 41°F …….. 33°F to 41°F

Frozen Food, °F ……………. -4°F to +4°F ……… -4°F to +4°F

Percent Running Time …… 35%-45% …………….. 50°F-70°F

EVAPORTOR FAN MOTOR

CONDENSER FAN MOTOR

-

REFRIGERATION SYSTEM

Minimum Compressor Capacity Vacuum ……………. 21 MIN. Minimum Equalized Pressure

Minimum Compressor Capacity Vacuum ……………. 21 MIN. Minimum Equalized Pressure

@ 70°F …………………………………………………… 49 PSIG

@ 70°F …………………………………………………… 49 PSIG

@ 90°F …………………………………………………… 56 PSIG

Refrigerant R134a …………………………………………… 4.93 oz.

Compressor ………………………………………………. 956 BTU/hr

INSTALLATION

Clearance must be provided at rear of the refrigerator for air circulation.

AT REAR ……………………………………………………………… 1 in

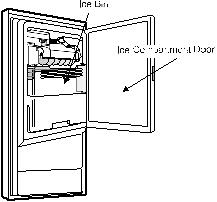

ICE ROOM

ICE ROOM

| Description |

795.7105* |

|

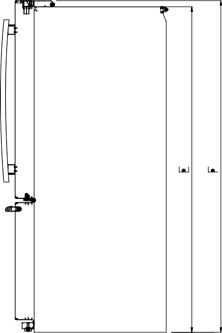

| Depth w/ Handles |

A |

35 3/8 in |

| Depth w/ Handles |

B |

32 7/8 in |

| Depth w/ o Door |

C |

29 in |

| Depth (Total with Door Open) |

D |

47 5/8 in |

| Height to Top of Case |

E |

68 3/8 in |

| Height to Top of Door Hinge |

F |

69 3/4 in |

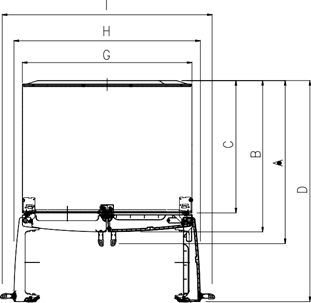

| Width |

G |

35 3/4 in |

| Width (door open 90 deg. w/o handle) |

H |

39 1/4 in |

| Width (door open 90 deg. w/ handle) |

I |

44 1/4 in |

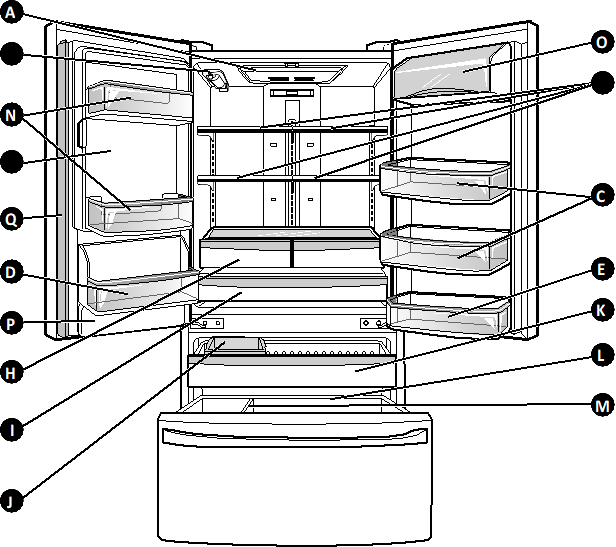

A Refrigerator Light B Filter (Inside)

C Modular Door Bins D Fixed Door Bin

C Modular Door Bins D Fixed Door Bin

Fixed Door Bin

Fixed Door Bin

-

Refrigerator Shelves G Ice Room

Refrigerator Shelves G Ice Room

(Ice Maker and Ice Bin)

H Humidity Controlled Crisper I Temperature Controlled

H Humidity Controlled Crisper I Temperature Controlled

Pantry Drawer

Extra Ice Bin

Extra Ice Bin

K Pullout Drawer L Durabase

Divider

Divider

-

Door Bins O Dairy Bin

Door Bins O Dairy Bin

P Water Tank Cover Q Mullion

P Water Tank Cover Q Mullion

- REMOVING AND REPLACING REFRIGERATOR DOORS

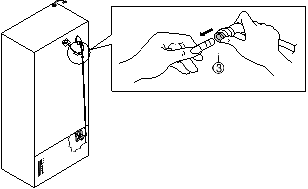

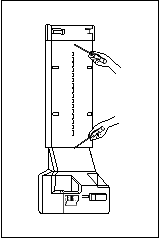

To remove the left refrigerator door:

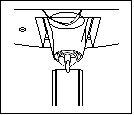

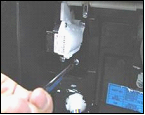

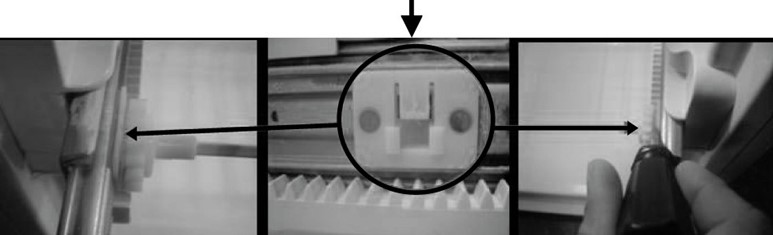

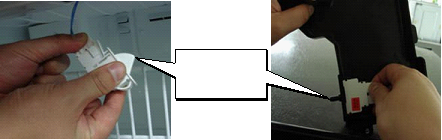

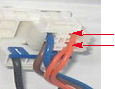

Pull the water tube out of the fitting while pressing the release ring on the fitting.

When you pull out the tube, first you have to push the collet by opposite direction of arrow in the upper picture and tube pull out by direction of arrow.

When you pull out the tube, first you have to push the collet by opposite direction of arrow in the upper picture and tube pull out by direction of arrow.

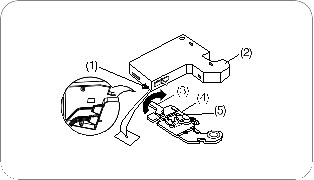

To remove the Right refrigerator door:

CAUTION: Before you begin, remove food and bins from the doors.

CAUTION: Before you begin, remove food and bins from the doors.

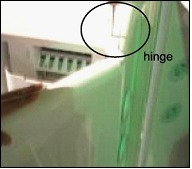

Open the door. Remove the top hinge cover screw (1).

Lift up the cover (2). Remove the cover.

Lift up the cover (2). Remove the cover.

Rotate the hinge lever (3) clockwise.

Lift the top hinge (4) free of the hinge lever latch (5). IMPORTANT: When lifting the hinge free of the latch, be careful that the door does not fall forward.

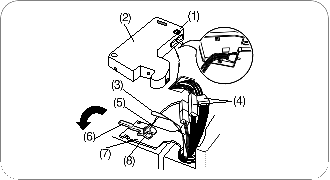

Open the door. Remove the top hinge cover screw (1). Use a flat-head screwdriver to pry back the hooks (not shown) on the front underside of the cover (2).

Open the door. Remove the top hinge cover screw (1). Use a flat-head screwdriver to pry back the hooks (not shown) on the front underside of the cover (2).

Lift up the cover.

Lift up the cover.

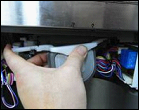

Remove the cover. Pull out the tube (3). Disconnect all the wire harnesses (4). Remove the grounding screw(5)

Rotate hinge lever (6) counterclockwise.

Lift the top hinge (7) free of the hinge lever latch (8).

IMPORTANT: When lifting the hinge free of the latch, be careful that the door does not fall forward.

Lift the door from the middle hinge pin and remove the

door.

Place the door, inside facing up, on a nonscratching surface.

-

DOOR

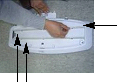

Mullion Removal

- Remove 2 screws.

- Lift mullion up carefully.

- Disconnect wire harness.

Door Gasket Removal

Door Gasket Removal

1. Remove gasket

Pull gasket free from gasket channel on the four remaining sides of door.

Door Gasket Replacement

1. Insert gasket into channel

1. Insert gasket into channel

Press gasket into channels on the four remaining sides of door.

Mullion Replacement

- Connect wire harness.

-

Insert mullion into channel.

Inserting mullion assy’ into bracket, door

-

Assemble 2 screws.

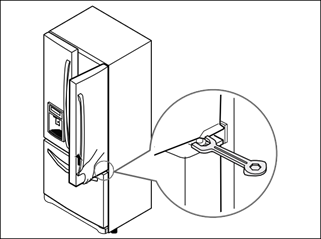

- Door Alignment

If the space between your doors is uneven, follow the instructions below to align the doors:

Remove the Base Grillie. Turn the leveling legs (CCW) to raise or (CW) to lower the height of the front of the refrigerator by using flat blade screw driver or 11/32″ wrench. Use the wrench (Included with the User Manual) to adjust the bolt in the door hinge to adjust the height. (CCW to raise or CW to lower the height.)

Remove the Base Grillie. Turn the leveling legs (CCW) to raise or (CW) to lower the height of the front of the refrigerator by using flat blade screw driver or 11/32″ wrench. Use the wrench (Included with the User Manual) to adjust the bolt in the door hinge to adjust the height. (CCW to raise or CW to lower the height.)

-

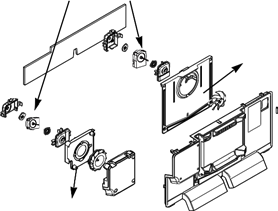

FAN AND FAN MOTOR(EVAPORATOR)

- Remove the freezer drawer. (If your refrigerator has an icemaker, remove the icemaker first)

- Remove the plastic guide for slides on left side by unscrewing phillips head screws.

- Remove the grille by removing four screws and pulling the grille forward.

- Remove the Fan Motor assembly by loosening 3 screws and disassembling the shroud.

Pull out the fan and separate the Fan Motor and Bracket.

Pull out the fan and separate the Fan Motor and Bracket.

- Ice Fan Scroll Assembly Replacement

- Remove the plastic guide for slides on left side by unscrewing phillips head screws.

- Pull out the cover sensor to disassemble using tools shown in the figure.

- Pull out the cover grille to disassemble using tools shown in the figure.

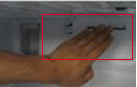

- Put your hand into the inside of grille to disassemble shown in the figure.

- Disconnect wire harness of the grille

- Remove the scroll assembly by loosening all screws

(1) (2)

(3) (4)

(5) (6)

-

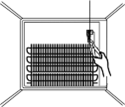

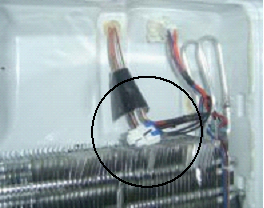

DEFROST CONTROL ASSEMBLY

Defrost Control assembly consists of Defrost Sensor and FUSE-M.

The Defrost Sensor works to defrost automatically. It is attached to the metal side of the Evaporator and senses its temperature. At 46F(8°C), it turns the Defrost Heater off.

Fuse-M is a safety device for preventing over-heating of the Heater when defrosting.

- Pull out the grille assembly. (Figure 1)

- Separate the connector with the Defrost Control assembly and replace the Defrost Control assembly after cutting the Tie Wrap. (Figure 2)

GRILLE ASSEMBLY DEFROST-CONTROL

ASSEMBLY

Figure 1 Figure 2

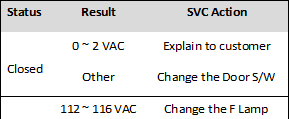

- LAMP

Unplug Refrigerator, or disconnect power at the circuit breaker.

If necessary, remove top shelf or shelves.

3-6-1 Refrigerator Compartment Lamp

- Release 2 screws.

- Hold both ends with your both hands and pull it downward to remove it.

- To remove the case lamp and cover lamp, release another 2 screws as following picture.

- Use a flat blade screwdriver as shown below to remove the cover lamp.

- To remove the LED Assembly, open the Hook part to pull it out as shown in the following picture.

-

MULTI DUCT

Remove the upper and lower Caps by using a flat screwdriver, and remove 2 screws. (Figure 3)

Remove the upper and lower Caps by using a flat screwdriver, and remove 2 screws. (Figure 3)

- Disconnect the lead wire on the bottom position.

-

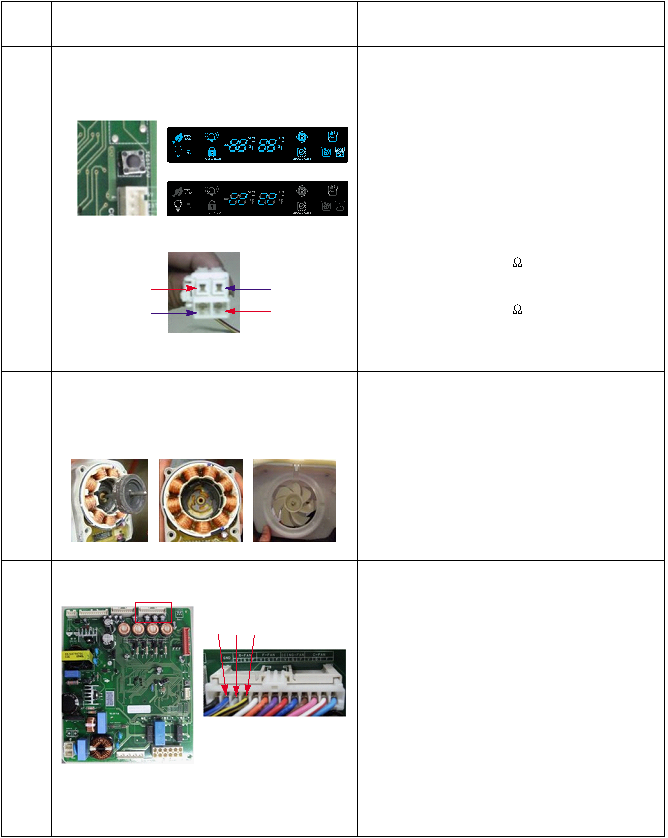

MAIN PWB

WARNING : Unplug the refrigerator before removing the control board.

WARNING : Unplug the refrigerator before removing the control board.

- Loosen the 3 screws on the PWB cover.

- Remove the PWB cover

Case, lamp

Case, lamp

Cover, lamp LED, Assembly

3-6-2 Freezer Compartment Lamp

- Unplug refrigerator power cord form outlet.

- Remove screw with driver.

- Grasp the cover Lamp,pull the cover downward.

Disconnect wire harness and replace the main PWB in the reverse order of removal.

Disconnect wire harness and replace the main PWB in the reverse order of removal.

3-9 DISPENSER

- Disconnect funnel by pulling down and forward.

Follow the steps in the pictures.

Follow the steps in the pictures.

- Use a flat blade screwdriver at bottom side hole of the “Cover Assembly dispenser” to detach hooks of the bottom side.

-

FUNNEL REPLACEMENT

- Pull up and out on the dispenser cover to remove.

- Remove 2 screws.

- Disconnect the wire harness.

- Replace in reverse order.

3) Hold the bottom side of the “Cover Assembly, dispenser” as shown in the picture, and pull and remove it. The cover dispenser is attached with a hook.

3) Hold the bottom side of the “Cover Assembly, dispenser” as shown in the picture, and pull and remove it. The cover dispenser is attached with a hook.

CAUTION: When replacing the dispenser cover in the reverse order of removal, be careful that the lead wire does not come out and the water tube is not pinched by the dispenser cover, as shown in the picture below.

CAUTION: When replacing the dispenser cover in the reverse order of removal, be careful that the lead wire does not come out and the water tube is not pinched by the dispenser cover, as shown in the picture below.

-

SUB PWB FOR WORKING DISPENSER

1) Loosen the screw on the sub PWB.

1) Loosen the screw on the sub PWB.

3-10 DISPLAY PWB REPLACEMENT

- Pull up and out on the dispenser cover to remove and replace PWB with dispenser cover.

- Pull the sub PWB down.

Disconnect the wire harness and replace the sub PWB in the reverse order of removal.

Disconnect the wire harness and replace the sub PWB in the reverse order of removal.

-

CAP DUCT REPLACEMENT

- Pull up and out on the dispenser cover to remove.

- Disconnect the wire harness.

- Remove the funnel.

- Replace in reverse order.

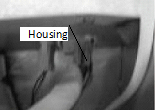

Contract the Housing.

Contract the Housing.

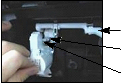

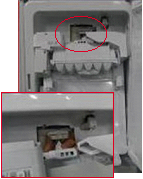

- CAP DUCT MOTOR REPLACEMENT

1) Separate the Housing of the Cap Duct Motor.

-

ICE CORNER DOOR REPLACEMENT

- Loosen the front screw as shown in the picture.

- Lift up the hinge with one hand.

- Pull out the Ice Corner Door with the other hand.

Unscrew 3 screws to disassemble the motor.

Unscrew 3 screws to disassemble the motor.

- When replacing to a new Motor, always check position of the Duct Door and Link to install the Motor.

Duct Door Link

Duct Door Link

Cap Duct Motor

NG Position

Assemble on the screws.

Assemble on the screws.

-

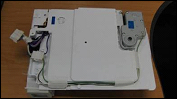

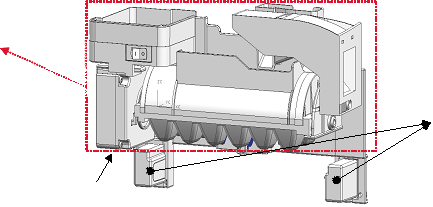

Icemaker replacement

- Remove the stainless screws marked in the picture below.

- Grasp the bottom of motor cover assembly and pull it out slowly.

- Disconnect wire harness from wall of compartment.

CAUTION : Make sure that the wire harness shown below is positioned properly in the clips on the back of the cover, and taped in place. If this harness is loose it will not allow the motor housung assembly to fit flush to the door liner.

In-door motor

In-door motor

-

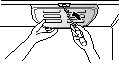

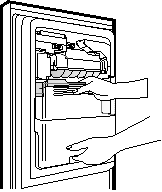

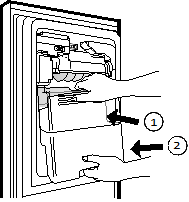

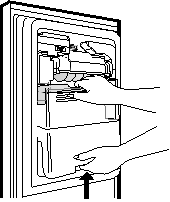

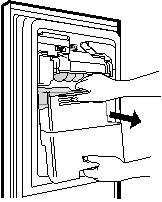

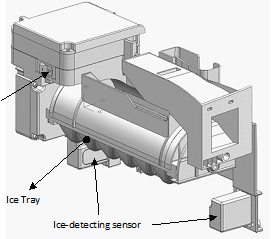

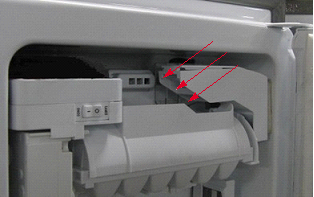

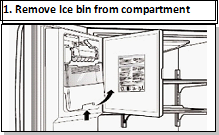

HOW TO REMOVE A ICE BIN

1) Grip the handles, as shown in the picture.

-

HOW TO INSERT A ICE BIN

- Insert the Ice Bin, slightly tilting it to avoid touching the Icemaker. (Especially, Ice-Detecting Sensor)

- Lift the lower part slightly.

- Take the Ice Bin out slowly.

-

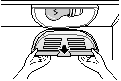

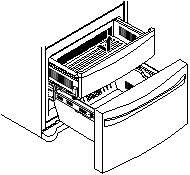

HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER

- Follow Steps to Remove

Step 1) Open the freezer door. Step 2) Remove the lower basket.

Step 3) Remove the two screws from the guide rails (one from each side).

Step 3) Remove the two screws from the guide rails (one from each side).

Step 4) Lift the freezer door up to unhook it from the rail support and remove.

Pull both rails to full extension.

Step 5) First: Remove the gear from the left side first by releasing the tab behind the gear, place a screwdriver between the gear and the tab and pull up on the gear.

Second: Remove the center rail.

Third: Remove the gear from the right side by following the same steps for the left side.

NOTE: THIS TAB MUST BE PUSHED IN TO RELEASE THE GEAR.

-

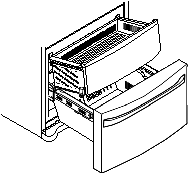

Follow Steps to Reinstall

Step 1) Reinstall the right side gear into the clip.

Step 2) Insert the rail into the right side gear. Gears do not need to be perpendicular to each other.

Step 4) The rail system will align itself by pushing the rails all the way into the freezer section.

Pull the rails back out to full extension.

Step 6) Reinstall the two screws into the guide rails (one from each side).

Step 3) Insert the rail into the left side gear, and insert the gear into the clip.

Step 5) Reinstall the freezer door by inserting the rail tabs into the guide rail.

Step 7) Reinstall the lower basket, and close the freezer door.

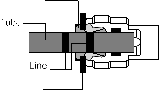

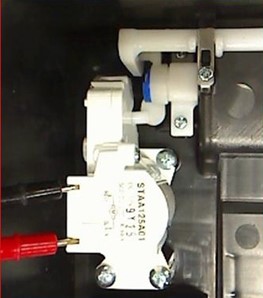

- WATER VALVE DISASSEMBLY METHOD

1) Turn off the water. Then separate the water line from the valve.

-

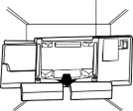

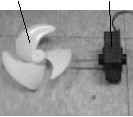

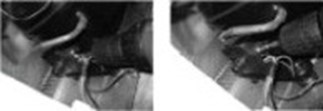

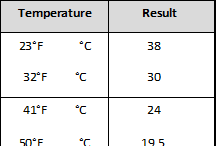

FAN AND FAN MOTOR DISASSEMBLY METHOD

- Using a short screwdriver, loosen one SCREW in DRAIN PIPE ASSEMBLY and one connected to the MOTOR COVER.

MOTOR COVER

MOTOR COVER

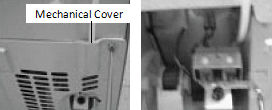

- Separate the Mechanical Cover and Valve Screw.

- Separate the housing and pull out the valve.

Befrore disconnecting the water lines, place a towel under the water valve to catch any water that may come out. Pull out the clip and press the collet to separte the water line from the valve.

Befrore disconnecting the water lines, place a towel under the water valve to catch any water that may come out. Pull out the clip and press the collet to separte the water line from the valve.

2) Pull and separate the FAN ASSEMBLY and MOTOR turning counterclockwise based on the MOTOR SHAFT.

FAN ASSEMBLY MOTOR

The assembly is in the reverse order of the disassembly and take special care for the following details.

- Be careful not to bend the tube during assembly.

- Press the WATER DISPENSER button until water pours out and check for leakage in the CONNECTOR TUBE (It differs by the water pressure but usually takes about 2 minutes until water pours out.)

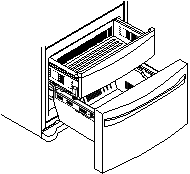

- PULL OUT DRAWER

To remove, pull the drawer out to full extension.

Lift the front of the drawer up, then pull it straight out.

To install, slightly tilt up the front and insert the drawer into the frame and push it back into place.

-

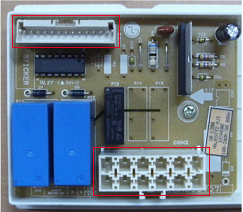

COMPRESSOR

-

Role

-

The compressor intakes low temperature and low pressure gas from the evaporator of the refrigerator and compresses this gas to high-temperature and high-pressure gas. It then delivers the gas to the condenser.

-

Note for Usage

- Be careful not to allow over-voltage and over-current.

- Do not drop or handle carelessly.

-

Keep away from any liquid.

If liquid such as oil or water enters the Cover PTC Compressor may fail due to breakdown of their insulating capabilities.

- Always use the Parts designed for the compressor and make sure it is properly attached to the compressor. Parts may appear physically identical but could have different electrical ratings. Replace parts by part number and model number. Use only approved substitute parts.

-

REMOVE THE COVER PTC

- Remove the Cover Back M/C

- Loosen two screws on comp base

- Use a L-shaped flap tooll to pry off the cover

- Assembly in reverse order of disassembly

4-2 Introduction of E-Linear Compressor

E-Linear compressor is run by mechanical part design through automatically varying the cooling power. The main parts consist of compressor and Sub PCB which controls the compressor. PCB authorizes constant voltage and constant frequency to the compressor and protects it.

E-Linear compressor is run by mechanical part design through automatically varying the cooling power. The main parts consist of compressor and Sub PCB which controls the compressor. PCB authorizes constant voltage and constant frequency to the compressor and protects it.

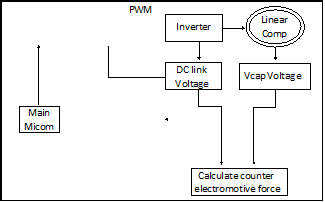

Control of Compressor Block Diagram

| Compressor Controller |

Signal |

|

Frequ |

|

-ency |

|

|

Counter elec- tromotive force |

|

Control Block Diagram of Compressor

-

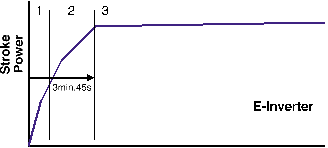

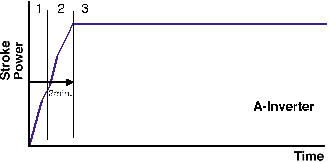

Compressor operating pattern

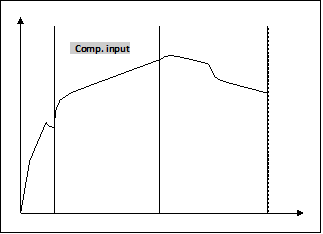

Drive half stroke after turning on initial power for 30 seconds. Then, slowly increase stroke and reach target input. Once reaching the target input, input naturally changes according to refrigerator load without any special control.

Drive half stroke after turning on initial power for 30 seconds. Then, slowly increase stroke and reach target input. Once reaching the target input, input naturally changes according to refrigerator load without any special control.

Interval 1) Half stroke interval – after initial running, stay at the initial value for 30 seconds

Interval 2) Running interval – Increase at every 0.8 till it reaches the target input; it takes about 3′ 45″

Interval 3) CVCF interval – Run by target voltage and main operating frequency and the input naturally changes according to refrigerator load

PWBDADSSEMBDLYYD,DDD SMADRDTDBUUZZZZEEDDRD

PWBDADSSEMBDLYYD,DDD SMADRDTDBUUZZZZEEDDRD

PWBDD ASSEMBDLYYD,DD AMBIENDTDLEDDD

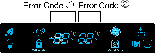

6-1. Error Code Summary

WARNING: When you check the Resistance values, be sure to turn off the power.

WARNING: When you check the Resistance values, be sure to turn off the power.

And wait for the voltage-discharge sufficiently.

NOTE) 3 hours before the error : Press the Ultra ICE button and Freezer button simultaneously 3 hours after the error : All errors, except for “Er rt”, “Er SS”, “Er IS(except for Icing sensor)”, “Er gF”, “Er It” error, are displayed.

NOTE) 3 hours before the error : Press the Ultra ICE button and Freezer button simultaneously 3 hours after the error : All errors, except for “Er rt”, “Er SS”, “Er IS(except for Icing sensor)”, “Er gF”, “Er It” error, are displayed.

“Er IS” which is displayed without input of user is the error of Icing Sensor.

NO

Error Detection CategoryError Display

Error Generation Factors

RemarkFreezer TemperatureFreezer Temperature1NormalityNoneNormal operation of Display2Freezer Sensor ErrorErFSShort or Disconnection of Freezer Sensor

Check each sensor and its connector.3Refrigerator Sensor ErrorErrSShort or Disconnection of Refrigerator Sensor4Defrosting Sensor ErrorErdSShort or Disconnection of Defrosting Sensor

5

Icing Sensor Error

Er

ISShort or disconnection of the sensor about Ice maker (Icing sensor, Ice maker sensor)6Pantry sensor errorErSSShort or Disconnection of Pantry Sensor7Room Temp Sensor ErrorErrtShort or Disconnectoin of Room temp.sensor

8

Ice maker kit defect

Er

It

Other Electric system error such as moter, gear, Hall IC, operation circuit within I/M kitWhen the ice does not drop even when the I/M Test S/W is pressed

(same as model applied Twisting Ice Maker before)

9Flow Meter(Sensor) Defect

Er

gFError of flow meter or water input or low water pressureError of flow meter or water input or low water pressure or flow meter connection

10

Poor Defrosting

Er

dHEven though it is passed

1 hour since then Defrosting, if Defrosting sensor is not over 46°F(8°C), it is causedTemperature Fuse Disconnection, Heater disconnection, DRAIN Jam, Poor Relay for Heater

11Abnormality of BLDC FAN Motor for Ice Making

Er

IFIt is caused when feedback signal isn’t over 65 seconds during BLDC FAN motor operating

Poor BLDC Motor connection, DRIVE IC, and TR

12Abnormality of BLDC FAN Motor for Freezer

Er

FFIt is caused when feedback signal isn’t over 65 seconds during BLDC FAN motor operating

Poor BLDC Motor connection, DRIVE IC, and TR

13Abnormality of BLDC FAN MOTOR For

Refrigerator

Er

rFIt is caused when feedback signal isn’t over 65 seconds during BLDC FAN motor operating

Poor BLDC Motor connection, DRIVE IC, and TR

14Abnormality of BLDC FAN Motor for Mechanic Room

Er

CFIt is caused when feedback signal isn’t over 65 seconds during BLDC FAN motor operating

Poor BLDC Motor connection, DRIVE IC, and TR

15

Communication Error

Er

CO

Communication Error between Micom of Main PCB and Display MicomPoor Communication connection,Poor TR of Transmitter and Receiver Tx/Rx between display and main board.

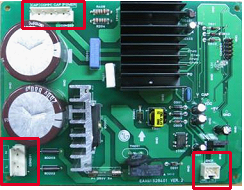

Main PCB

Main PCB

| P/No & MFG |

Picture |

|||

|

CON1 |

CON8 |

|||

|

CON6 |

||||

|

EBR65002701 (2010.02~) |

CON2 |

CON5 |

||

|

CON4 |

||||

|

CON3 |

||||

|

CON10 |

||||

|

EBR64173902 (2010.02~) Refer to 48Page |

CON203 CON201 |

CON2 |

||

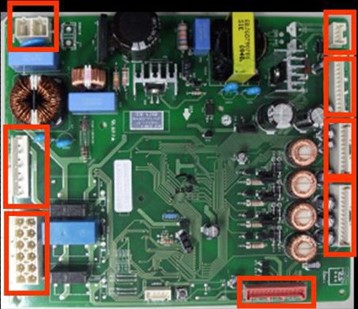

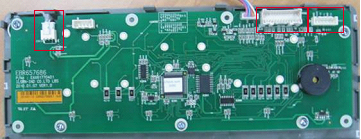

- Display PCB & Sub PCB

|

P/No |

Picture |

|||

|

Display PCB EBR65768601 (2010.02~) |

|

|||

|

CON104 |

CON102 CON101 |

|||

|

Sub PCB EBR60070704 (2010.02~) |

CON1 |

CON2 |

||

Troubleshooting With Error Display

Troubleshooting With Error Display

- Freezer Sensor Error (Er FS)

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check for a loose connection. |

|

|

2 |

Check the Blue/White to

<CON6> |

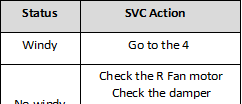

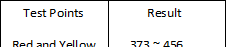

<Temperature table-1>

For example, |

- Refrigerator Sensor Error (Er rS)

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check for a loose connection. |

|

|

2 |

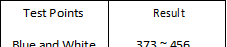

Check the White to White.

<CON6> |

<Temperature table-2>

For example, |

- Icing Sensor Error (Er IS)

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check for a loose connection. |

|

|

2 |

Check the Blue to Blue.

<Display> <CON101> |

<Temperature table-1>

For example, |

- Defrost Sensor Error (F dS)

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check for a loose connection.

|

|

|

2 |

Check the Orange to Orange.

Check the Brown to Brown.

<CON6> |

<Temperature table-3>

For example, |

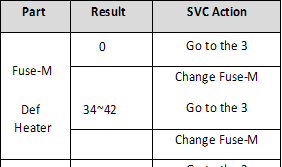

Defrost Heater Error (Er dH)

Defrost Heater Error (Er dH)

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check the Door gasket. |

|

|

2 |

Check the Defrost control part. Fuse M Sensor Def Heater |

|

|

3 |

Input Test 3 Mode. (Push the button 3 times) |

|

|

4 |

Check the Blue to Orange.

<CON3> |

|

|

5 |

Release the test mode. push the button 1 times. (normal) |

|

|

6 |

Check the Blue to Orange.

<CON3> |

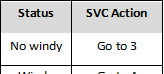

- Freezer Fan Error (Er FF)

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Reset the unit and Input Test 1 Mode. (Push the button 1 time) |

|

|

2 |

Open the freezer door and Check the air flow.

|

|

|

3 |

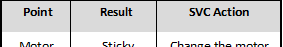

Check the Fan motor.

|

Rotate fan using your hand. It feel sticky, change the motor. (cause of ice or rust inside of motor) |

|

4 |

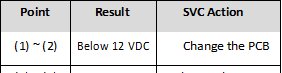

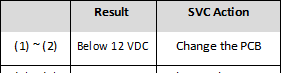

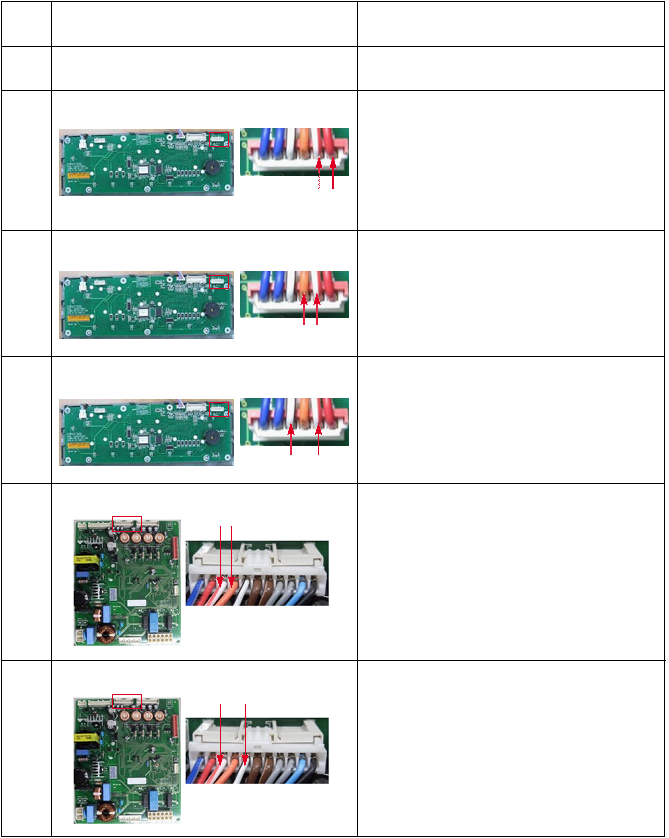

Check the Fan motor voltage. (1) (2) (3)

<CON4> |

- Icing Fan Error (Er IF)

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Reset the unit and Input Test 1 Mode. (Push the button 1 time) |

|

|

2 |

Open the refrigerator door and Check the air flow.

|

|

|

3 |

Check the Connector (Frozen caused the PCB short)

|

To protect ice short, add wire seal in connector. We developed new type connector, so order the new type.

Wire seal (Silicon) |

|

4 |

Check the Fan motor. (Frozen, Lock, ect.)

|

|

|

5 |

Check the Fan motor voltage. (1) (2) (3)

<CON4> |

- Condenser Fan Error (Er CF)

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Reset the unit and Input Test 1 Mode. (Push the button 1 time) |

|

|

2 |

Check the fan rotating.

|

|

|

3 |

Check the Fan motor and surrounding.

|

Rotate fan using your hand. It feel sticky, change the motor. |

|

4 |

Check the Fan motor voltage. (1) (2) (3)

<CON4> |

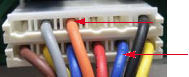

- Communication Error (Er CO)

No Checking flow

- Check the loose connection.

- Check the Red to White Red.

<CON101>

Result & SVC Action

Check the Orange to Brown.

Check the Orange to Brown.

<CON101>

Check the Orange to Red.

Check the Orange to Red.

<CON101>

- Check the White/Red to Orange.

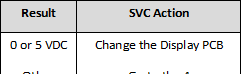

|

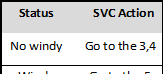

Result |

SVC Action |

|

0 or 5 VDC |

Change the Display PCB |

|

Other |

Go to the 6 |

<CON5>

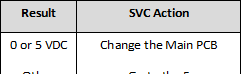

- Check the White Red to White/Black.

|

Result |

SVC Action |

|

0 or 5 VDC |

Change the Main PCB |

|

Other |

Explain to customer |

<CON5>

Troubleshooting Without Error Display

Troubleshooting Without Error Display

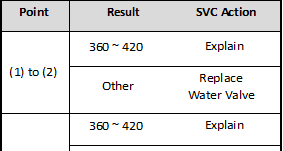

Cube mode doesn’t work

Cube mode doesn’t work

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check the loose connection. |

|

|

2 |

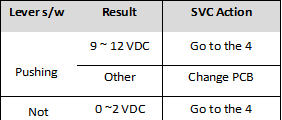

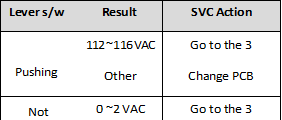

Check the Black to White. (While pushing the lever S/W)

<CON2> |

|

|

3 |

Check the RED to White Red. (While pushing the lever S/W)

<CON1> |

|

|

4 |

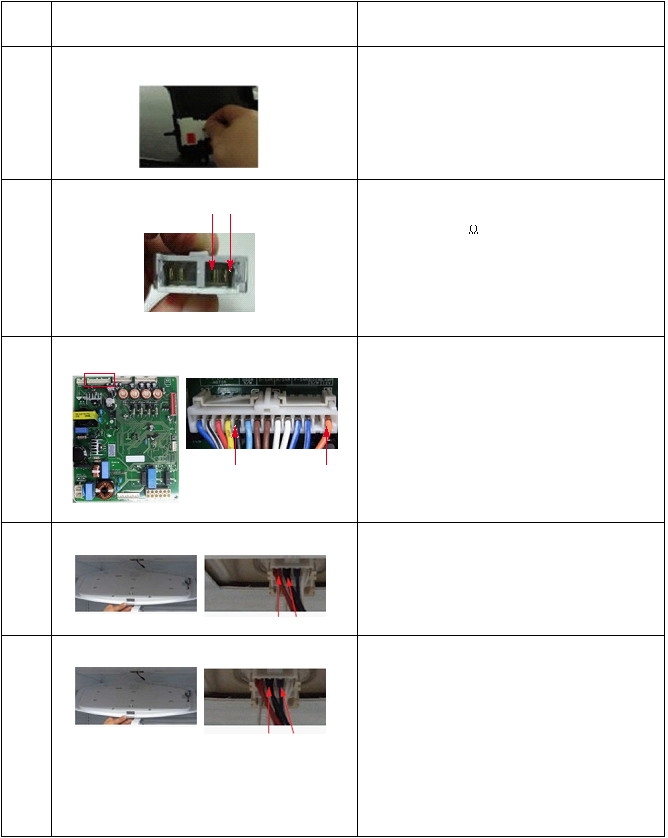

Check the resistance value.

<Ice Maker> (1) (2) (3) (4) <Geared Motor> <Dispenser Motor> |

|

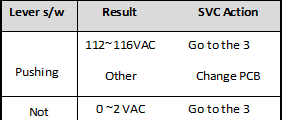

Crush mode doesn’t work

Crush mode doesn’t work

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check the loose connection. |

|

|

2 |

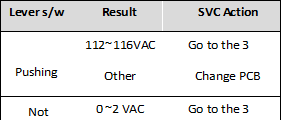

Check the Sky Blue to White. (While pushing the lever S/W)

<CON2> |

|

|

3 |

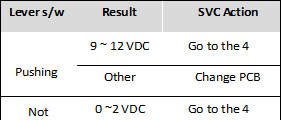

Check the RED to White Red. (While pushing the lever S/W)

<CON1> |

|

|

4 |

Check the resistance value.

<Ice Maker> (3) (1) (2) (4) <Geared Motor> <Dispenser Motor> |

|

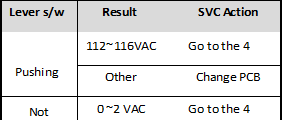

Water mode doesn’t work

Water mode doesn’t work

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check the loose connection. |

|

|

2 |

Check the Purple to White. (While pushing the lever S/W)

<CON2> |

|

|

3 |

Check the Blue to Gray. (While pushing the lever S/W)

<CON3> |

|

|

4 |

Check the resistance value. (1) (2) (3) (4) Dispenser Ice Maker <Pilot Valve> <Water Valve> Machine Room In door |

|

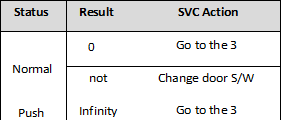

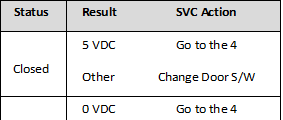

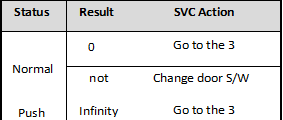

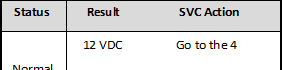

- Freezer room LED lamp doesn’t work

No Checking flow Result & SVC Action

- Check the Freezer door switch. If feel sticky, Change the door s/w.

Check the door S/W resistance.

Check the door S/W resistance.

Check the Black to Sky blue.

Check the Black to Sky blue.

<CON6>

Check the Blue to Black.

Check the Blue to Black.

<CON3>

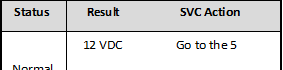

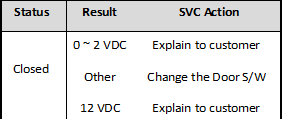

- Refrigerator room lamp doesn’t work

No Checking flow Result & SVC Action

- Check the Refrigerator door switch. If feel sticky, Change the door s/w.

Check the door S/W resistance.

Check the door S/W resistance.

Check the Black to Orange.

Check the Black to Orange.

<CON6>

Check the Red to BLue.

Check the Red to BLue.

Check the Red to BLue.

Check the Red to BLue.

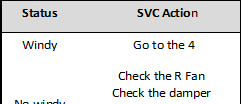

Poor cooling in Fresh food section

Poor cooling in Fresh food section

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check the sensor resistance.

<CON6>

For example, |

|

|

2 |

Reset the unit and Input Test 1 Mode. (Push the button 1 time) |

|

|

3 |

Open the fresh food door and Check the air flow. |

|

|

4 |

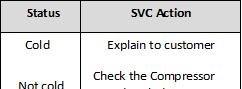

Check the air temperature. Cold or not ? |

No Checking flow

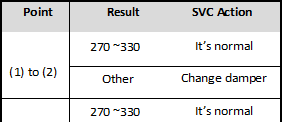

5 Damper checking method. Inputting TEST Mode, Check the damper and PCB.

(3)

(1)

Result & SVC Action

|

Test Mode |

Damper State |

SVC Action |

|

1 Mode |

Open |

Damper is normal. (Check the |

|

2 Mode |

Closed |

|

|

1,2 mode |

Not working |

Change the damper |

(2) (4)

(2) (4)

-

Check the Fan motor. Rotate fan using your hand.

Check the Fan motor. Rotate fan using your hand.

It feel sticky, change the motor. (Cause of ice or rust inside of motor)

Check the R Fan motor voltage.

Check the R Fan motor voltage.

(1) (2) (3)

<CON4>

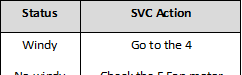

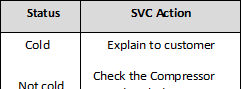

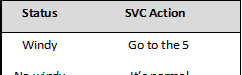

Poor cooling in Freezer compratment

Poor cooling in Freezer compratment

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check the sensor resistance.

<CON6>

For example, |

|

|

2 |

Reset the unit and Input Test 1 Mode. (Push the button 1 time) |

|

|

3 |

Open the freezer door and Check the air flow. |

|

|

4 |

Check the air temperature. Cold or not ? |

Over cooling in Fresh food compartment

Over cooling in Fresh food compartment

|

No |

Checking flow |

Result & SVC Action |

|

1 |

Check the sensor resistance.

<CON6>

For example, |

|

|

2 |

Reset the unit and Input Test 1 Mode. (Push the button 1 time) |

|

|

3 |

Open the refrigerator door and Check the air flow. |

|

|

4 |

Input Test 2 Mode and Check the air flow. (Push the button 1 time)

|

|

|

5 |

Check the damper resistance. (3) (1) (2) (4) |

|

- Reference

TEST MODE and Removing TPA

TEST MODE and Removing TPA

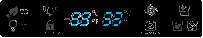

- How to make TEST MODE

If you push the test button on the Main PCB, the refrigerator will be enter the TEST MODE.

- 1 time : Comp / Damper / All FAN on (All things displayed)

-

2 times : Damper closed

(22 22 displayed)

-

3 times : Forced defrost mode

(33 33 displayed)

Main PWB

-

How to remove Terminal Position Assurance (TPA)

<AC TPA> <DC TPA>

After measure the values, you should put in the TPA again.

-

Wire Color

BL : Blue WH : White

BO : Bright Orange BK : Black

BN : Brown PR : Purple RE : Red

GN : Green SB : Sky Blue GY : Gray

BL/WH : Blue & White WH/RD : White & Red YL/BK : Yellow & Black

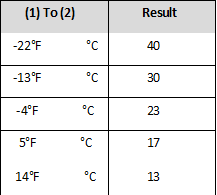

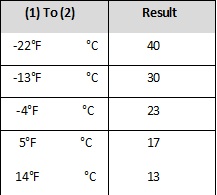

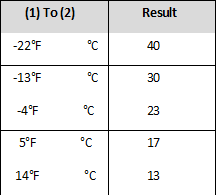

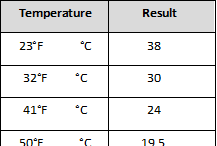

- TEMPERATRUE CHART – FRZ AND ICING SENSOR

| TEMP |

RESISTANCE |

VOLTAGE |

| -39°F (-40°C) |

73.29 |

4.09 V |

| -30°F (-35°C) |

53.63 |

3.84 V |

| -21°F (-30°C) |

39.66 |

3.55 V |

| -13°F (-25°C) |

29.62 |

3.23 V |

| -4°F (-20°C) |

22.33 |

2.89 V |

| 5°F (-15°C) |

16.99 |

2.56 V |

| 14°F (-10°C) |

13.05 |

2.23 V |

| 23°F (-5°C) |

10.10 |

1.92 V |

| 32°F (0°C) |

7.88 |

1.63 V |

| 41°F (5°C) |

6.19 |

1.38 V |

| 50°F (10°C) |

4.91 |

1.16 V |

| 59°F (15°C) |

3.91 |

0.97 V |

| 68°F (20°C) |

3.14 |

0.81 V |

| 77°F (25°C) |

2.54 |

0.67 V |

| 86°F (30°C) |

2.07 |

0.56 V |

| 95°F (35°C) |

1.69 |

0.47 V |

| 104°F (40°C) |

1.39 |

0.39 V |

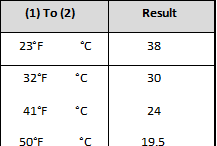

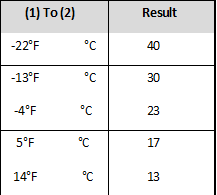

- TEMPERATRUE CHART – REF AND DEF SENSOR

| TEMP |

RESISTANCE |

VOLTAGE |

| -39°F (-40°C) |

225.1 |

4.48 V |

| -30°F (-35°C) |

169.8 |

4.33 V |

| -21°F (-30°C) |

129.3 |

4.16 V |

| -13°F (-25°C) |

99.30 |

3.95 V |

| -4°F (-20°C) |

76.96 |

3.734 V |

| 5°F (-15°C) |

60.13 |

3.487 V |

| 14°F (-10°C) |

47.34 |

3.22 V |

| 23°F (-5°C) |

37.55 |

2.95 V |

| 32°F (0°C) |

30 |

2.67 V |

| 41°F (5°C) |

24.13 |

2.40 V |

| 50°F (10°C) |

19.53 |

2.14 V |

| 59°F (15°C) |

15.91 |

1.89 V |

| 68°F (20°C) |

13.03 |

1.64 V |

| 77°F (25°C) |

10.74 |

1.45 V |

| 86°F (30°C) |

8.89 |

1.27 V |

| 95°F (35°C) |

7.40 |

1.10 V |

| 104°F (40°C) |

6.20 |

0.96 V |

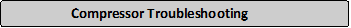

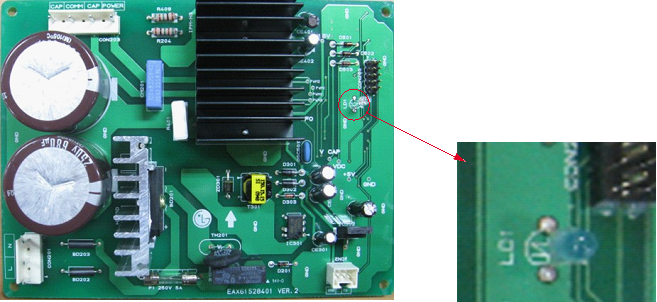

Step 1) Open PWB cover Step 2) Check for blinking frequency of LED, PWB

If compressor is normal, it does not blink

: Refer to the next page to find out what actions to take according to how many times LED blink

| No |

LED operating condition |

Cause |

Service guideline |

|

|

1 |

LED two – time repetiton

on – on – off – on – on – off – on – on – off repeating |

PCB part defect (piston overrun) |

|

|

|

LED four – time repetiton

on – on – on – on – off – on – on – on – on – off repeating |

1.After resetting |

|||

|

power, check if it is |

||||

|

running normal |

||||

|

2.If the same |

||||

|

2 |

outlet clogging |

symptom arises after the first action, replace PCB |

||

|

3.If the same |

||||

|

symptom arises after |

||||

|

the second action, |

||||

|

replace compressor |

||||

|

LED five – time repetiton

on – on – on – on – on – off – on – on – on – on – on – off repeating |

1. After resetting |

|||

|

power, check if it is |

||||

|

running normal |

||||

|

2. If the same |

||||

|

3 |

piston constraint |

symptom arises after the first action, replace PCB |

||

|

3. If the same |

||||

|

symptom arises after |

||||

|

the second action, |

||||

|

replace compressor |

||||

|

LED six – time repetiton

on – on – on – on – on – on – off – on – on – on – on – on – on – off |

repeating |

1. After resetting |

||

|

power, check if it is |

||||

|

running normal |

||||

|

4 |

circuit overcurrent error |

If the same symptom arises after the first action, replace PCB If the same symptom |

||

|

arises after the |

||||

|

second action, |

||||

|

replace compressor |

||||

|

LED seven- time repetiton

on – on – on – on – on – on – on – off – on – on –on – on – on – on– on – off repeating |

1.After resetting |

|||

|

power, check if it is |

||||

|

5 |

PCB part defect (IPM) |

running normal 2. If the same symptom arises after the first action, |

||

|

replace PCB |

||||

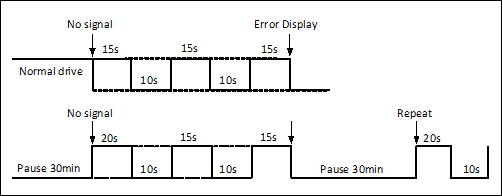

- How to check the Fan-Error

(1) EBR650027

After sending a signal to the fan, the MICOM checks the BLDC fan motor s lock status. If there is no feedback signal from the BLDC fan, the fan motor stops for 10 seconds and then is powered again for 15 seconds. To determine that there is a fan motor malfunction,

this process is repeated 3 times. If the fan motor is determined to be defective, the error code will be shown in the display for 30 minutes.

At this point, the process will be repeated until the fan motor operates normally. If normal operation is achieved, the error display is erased and the MICOM is reset automatically.

COMPONENT TESTING INFORMATION

COMPONENT TESTING INFORMATION

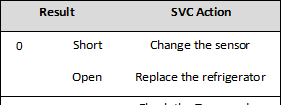

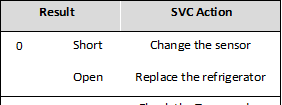

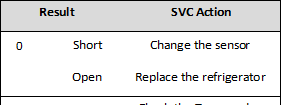

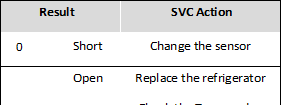

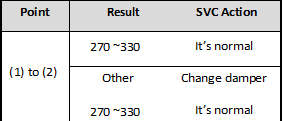

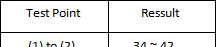

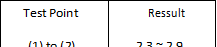

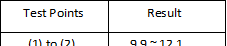

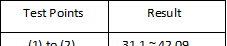

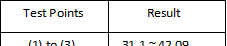

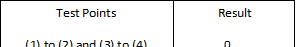

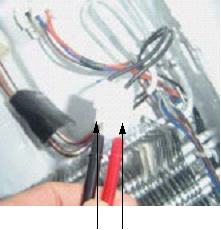

Defrost Controller Assembly

|

Function |

|

|

|

How to Measure (Fuse-M) |

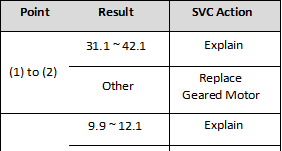

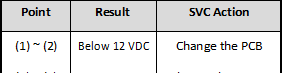

(1) to (2) |

Set a ohmmeter to the 2 housing pin. Measure the 2 pin connected to Fuse-M. If the ohmmeter indicate below 0.1ohm fuse-m is a good condition, But infinitely great ohm Fuse-M is disconnection |

|

How to Measure (Sensor) |

(1) to (2) |

Set a ohmmeter to The 2housing pin. Measure the 2 pin connected to Sensor. If the ohmmeter indicate When check the ohm at other temperature Check the sensor manual. |

|

Standard |

Fuse-M (at all temperature)

|

Sensor (at room temperature)

|

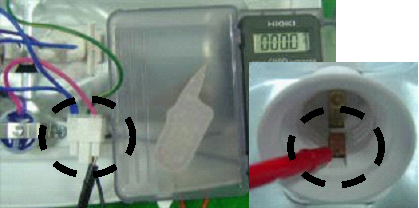

- Sheath Heater

|

Function |

Sheath heater is a part for defrost. All heating wire is connected to only one line. So we can decide part is defect or not when we check the resistance. |

|

How to Measure |

(1) (2) Set a ohmmeter connect to The 2 housing pin. Measure the 2 pin connected to Sheath Heater. If the ohmmeter indicate (V°øV)/Watt=R is good condition, ex) when watt=350w, voltage=115v R=(115°ø115)/350=38 Sheath heater is disconnection |

|

Standard |

Sheath heater (at all temperature)

|

Door Heater Assembly

Door Heater Assembly

| Function |

The heater is |

designed |

to |

prevent |

the raising dew from door. |

|||

| How to | ||||||||

| Measure | ||||||||

|

1 |

|

|||||||

|

3 |

2 |

|

||||||

|

6 |

4 |

5 |

||||||

|

7 |

||||||||

| 8 | ||||||||

|

9 |

||||||||

| Standard |

|

|||||||

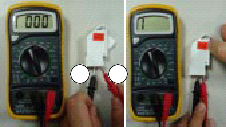

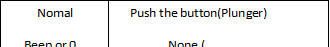

- Door Switch

|

Function |

The switch sense if the door open or close.

When the door open, internal contact operate on and off moving plunger of door switch up and down. |

|

How to Measure |

<Switch, Freezer> <Switch, Refrigerator> Button (Plunger) 1 2 3 4 1 2 3 4 3 4 2 1 Beep Beep Check the resistance between connectors 1, 2 and 3, 4 .It means check whether or not applying an electric current. If there is resistance, it means the switch not inferiority |

|

Standard |

Multimeter beep – Switch F,R

|

Dispenser DC Motor

Dispenser DC Motor

|

Function |

– Dispenser DC Motor : When customer push the dispenser button, Pull duct door and abstract from ice bank. |

|

How to Measure |

(1) (2) Dispensor DC Motor |

|

Standard |

Dispenser DC Motor

|

AC Motor ASSEMBLY

AC Motor ASSEMBLY

|

Function |

The In-door motor of AC motor assembly pushes ices to the dispenser. |

|

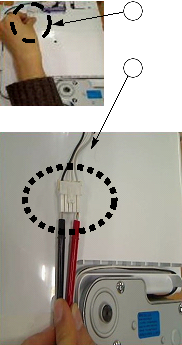

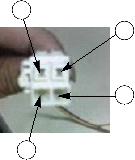

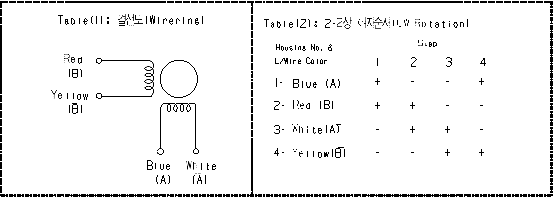

How to Measure |

< In-door Motor > < In-door Motor >

(1) (2) (1) (3) Check the resistance between connectors (In-door motor 1, 2) and (In-door motor 1, 3). It means check whether or not applying an Electric current. If there is resistance, it means the geared motor or solenoid is not inferiority |

|

Standard |

Geared Motor Cube Solenoid

|

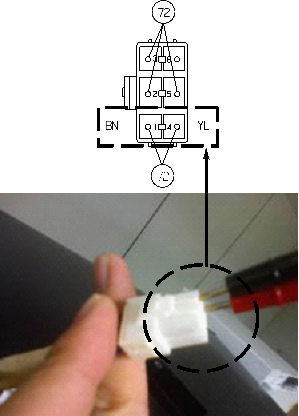

Damper

Damper

|

Function |

The damper supplies the cold air at freezer room to chillroom by using the damper’s plate. Chillroom is colder than before when damper’s plate is open. When damper’s plate is close, chillroom’s temperature will rise. |

|

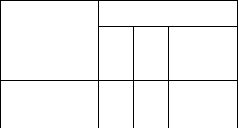

How to Measure |

< Damper Circuit > 1 Blue 1 Blue

3 White

3 Yellow Check the 1 , 3 < extension >

Check the 2 , 4 Check the 1 , 3 Check the resistance between connectors 1,3 and 2,4 .It means check whether or not applying an electric current. If there is resistance, it means the damper not inferiority |

|

Standard |

Damper

|

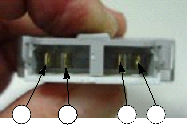

Lamp Socket

Lamp Socket

|

Function |

The lamp socket connect cover lamp assembly to lamp. The lamp socket fix lamp and unite lamp and cover lamp assembly. The lamp socket supply electric source to lamp also. |

|

How to Measure |

(1) (2) (3) (4) Check the resistance between connector of housing and connector of lamp socket. It means check whether or not applying an electric current. If there is resistance it means the lamp socket is not inferiority. |

|

Standard |

|

Flow Sensor

Flow Sensor

|

Function |

Flow Sensor (in machine room) Count the water quantity from city water to water filter in refrigerator |

|

How to Measure |

Flow Sensor (in machine room) |

|

Standard |

|

- TROUBLESHOOTING

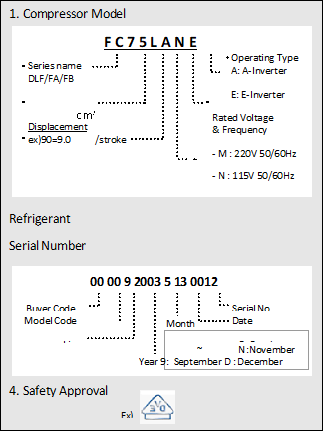

- INFORMATION OF LINEAR COMPRESSOR

The information tag provides compressor model, refrigerant, serial number and safety approval

The information tag provides compressor model, refrigerant, serial number and safety approval

Compressor Label

Name Plate

Name Plate

Size : 90mm X 20mm

Size : 90mm X 20mm

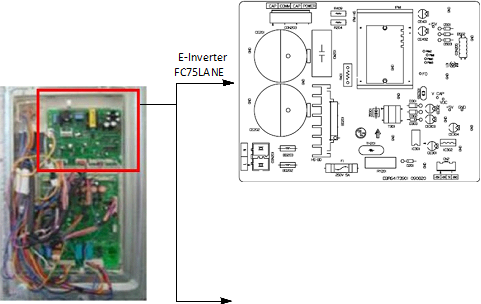

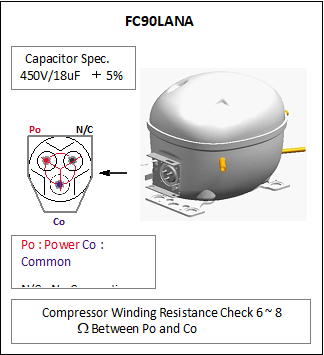

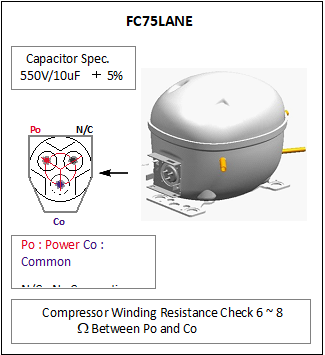

There are two types of controllers used in the linear compressor system.

There are two types of controllers used in the linear compressor system.

- The “E”-inverter system is used with the FC75LANE compressor.

- The “A”-inverter system is used with the FC90LANA compressor.

Refrigerator

Refrigerator

Comp Drive

Compressor

FC75LANE

FC75LANE

E-Inverter System

FC90LANA

FC90LANA

A-Inverter System

*VVVF : Variable Voltage Variable Frequency

**CVCF : Constant Voltage Constant Frequency

To reduce noise level, the piston stroke is slowly increased to full power during start up.

To reduce noise level, the piston stroke is slowly increased to full power during start up.

Step 1) Start up – Half stroke interval for first 30 seconds.

Step 1) Start up – Half stroke interval for first 30 seconds.

Step 2) Ramp up – Stroke increases every 0.8sec until maximum stroke length is reached (about 3 min, 15 sec)

Step 3) CVCF interval – 180V / 60Hz

Step 1) Start up – Half stroke interval for first 20 seconds.

Step 1) Start up – Half stroke interval for first 20 seconds.

Step 2) Ramp up – Stroke increases until maximum stroke length is reached (about 1 min, 40 sec)

Step 3) VVVF interval – target voltage and frequency controlled by Control Board signals

There are 6 protection logics designed to protect the linear compressor system. When a failure is detected, the compressor will shut and will try to restart after a set period of time for each type of failure. The LED located on the inverter drive PCB will flash the appropriate code to indicate the detected failure. This code will continue to flash until the unit is disconnected from the power source.

There are 6 protection logics designed to protect the linear compressor system. When a failure is detected, the compressor will shut and will try to restart after a set period of time for each type of failure. The LED located on the inverter drive PCB will flash the appropriate code to indicate the detected failure. This code will continue to flash until the unit is disconnected from the power source.

Inverter Error Codes

App.RequirementWaiting TimeThe number of LED flashesFCT0A-Inv.Compressor current and voltage error.20 sec.1Stroke TripE-Inv.

A-Inv.Piston stroke overrun detected.1 min.2Locked Piston TripE-Inv.

A-Inv.Piston is locked.2 min. 30 sec.5Current TripE-Inv.

A-Inv.Current overload detected.2 min. 30 sec.6IPM FaultE-Inv.

A-Inv.High current detected due to IPM failure.2 min. 30 sec.7Communication ErrorA-Inv.Miscommunication with Refrigerator08

Bridge Diodes converts 115V AC (Alternating current) to 115V DC (Direct current) The Voltage Multiplying circuit then increases the 115V DC to 230V DC.

Bridge Diodes converts 115V AC (Alternating current) to 115V DC (Direct current) The Voltage Multiplying circuit then increases the 115V DC to 230V DC.

Then the IPM (Intelligent Power Module) converts the 230V DC to 230V AC.

The converted AC power can be regulated to any required voltage and frequency.

There are two PCB located behind the PCB cover. One is the main PCB, and the other is the driver PCB the linear compressor.

There are two PCB located behind the PCB cover. One is the main PCB, and the other is the driver PCB the linear compressor.

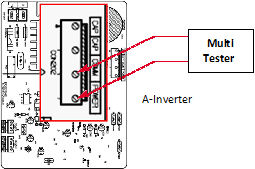

A-Inverter FC90LANA

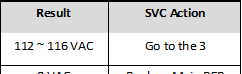

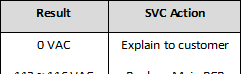

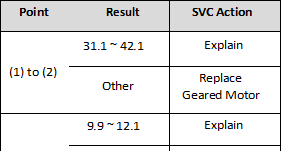

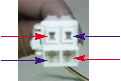

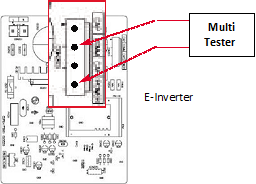

Measure the voltage at locations on the connector (as shown picture) with a multi-tester.

Measure the voltage at locations on the connector (as shown picture) with a multi-tester.

IPM Voltage Check

To ensure proper diagnosis, make sure that the unit has been plugged in for at least 10 min.

To ensure proper diagnosis, make sure that the unit has been plugged in for at least 10 min.

To determine if the compressor is receiving the proper voltage, check the PCB output voltage during operation.

To determine if the compressor is receiving the proper voltage, check the PCB output voltage during operation.

Normal operating voltage will be between 80V AC and 180V AC.

Normal operating voltage will be between 80V AC and 180V AC.

Note : Higher voltage readings may occur under “heavy” load conditions.

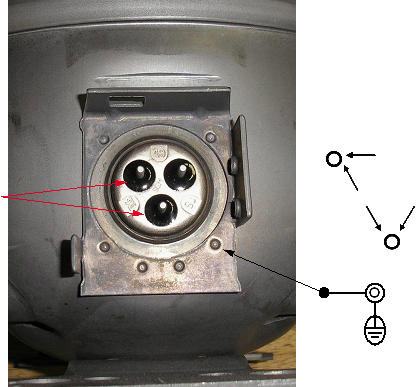

Insulation check : Check for infinite Ohms between all compressor terminal and ground.

Insulation check : Check for infinite Ohms between all compressor terminal and ground.

LG Linear Compressor

NOTE : Any Terminal to Ground should read Inf ( ~ )

NOTE : Any Terminal to Ground should read Inf ( ~ )

Inf (~)

Inf (~)

6 ~ 8 6 ~ 8 Inf (~)

GN

GND

-

SERVICE DIAGNOSIS CHART

| COMPLAINT |

POINTS TO BE CHECKED |

REMEDY |

| No Cooling. |

|

|

| Cools poorly. |

|

|

| Food in the Refrigerator is frozen. |

|

|

| Condensation or ice forms inside the unit. |

|

|

| Condensation forms in the Exterior Case. |

|

|

| There is abnormal noise. |

|

|

| Door does not close well. |

|

|

| Ice and foods smell unpleasant. |

|

|

Other possible problems:

Other possible problems:

|

Check if frost forms in the freezer. |

Not defrosting |

Check Components of the defrosting circuit. |

||

|

Check the refrigeration system. |

The system is faulty. |

Perform sealed system repair. |

||

|

Check the Thermistor. |

The operation of the Thermistor is incorrect. |

Replace the Thermistor. |

||

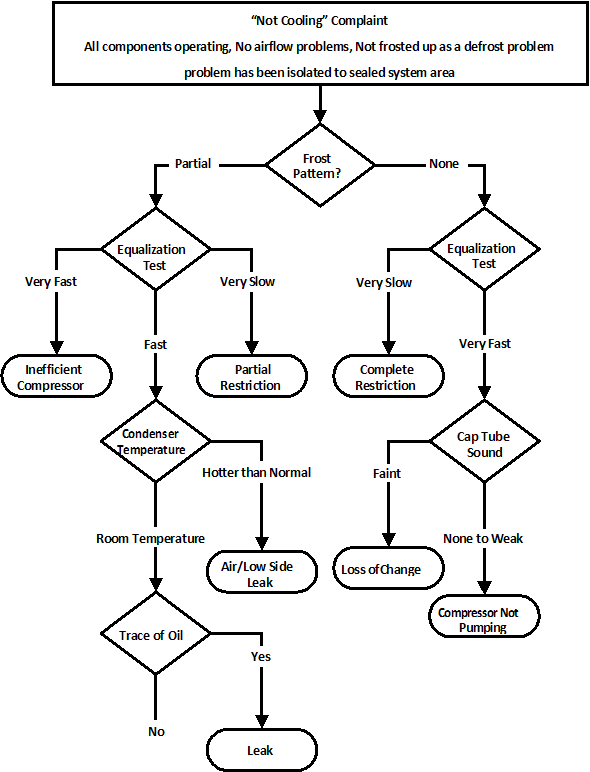

- REFRIGERATION CYCLE

Troubleshooting Chart

Troubleshooting Chart

|

CAUSE |

STATE OF THE UNIT |

STATE OF THE EVAPORATOR |

TEMPERATURE OF THE COMPRESSOR |

REMARKS |

|

|

LEAKAGE |

PARTIAL LEAKAGE |

Freezer compartment and Refrigerator don’t cool normally. |

Low flowing sound of Refrigerant is heard and frost forms in inlet only. |

A little higher than ambient temperature. |

|

|

COMPLETE LEAKAGE |

Freezer compartment and Refrigerator don’t cool normally. |

Flowing sound of refrigerant is not heard and frost isn’t formed. |

Equal to ambient temperature. |

|

|

|

CLOGGED BY DUST |

PARTIAL CLOG |

Freezer compartment and Refrigerator don’t cool normally. |

Flowing sound of refrigerant is heard and frost forms in inlet only. |

A little higher than ambient temperature. |

|

|

WHOLE CLOG |

Freezer compartment and Refrigerator don’t cool. |

Flowing sound of refrigerant is not heard and frost isn’t formed. |

Equal to ambient temperature. |

|

|

| MOISTURE CLOG |

Cooling operation stops periodically. |

Flowing sound of refrigerant is not heard and frost melts. |

Lower than ambient temperature. |

|

|

| DEFECTIVE COMPRESSION |

COMP- RESSION |

Freezer and Refrigerator don’t cool. |

Low flowing sound of refrigerant is heard and frost forms in inlet only. |

A little higher than ambient temperature. |

|

|

NO COMP- RESSION |

No compressing operation. |

Flowing sound of refrigerant is not heard and there is no frost. |

Equal to ambient temperature. |

|

|

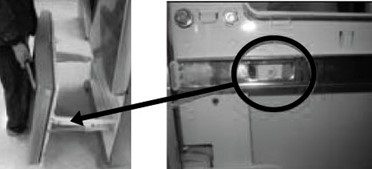

- Cleaning

There is no need for routine condenser cleaning in normal Home operating environments. If the environment is particularly greasy or dusty, or there is significant pet traffic in the home, the condenser should be cleaned every 2 to 3 months to ensure maximum efficiency.

If you need to clean the condenser: Remove the mechanical cover.

If you need to clean the condenser: Remove the mechanical cover.

Use a vacuum cleaner with a soft brush to clean the grille, the open areas behind the grille and the front surface area of the condenser.

Use a vacuum cleaner with a soft brush to clean the grille, the open areas behind the grille and the front surface area of the condenser.

Replace the mechanical cover.

Replace the mechanical cover.

- SEALED SYSTEM DIAGNOSIS

(The equalization test is trying to restart a compressor using a start kit after it has been operating.)

(The equalization test is trying to restart a compressor using a start kit after it has been operating.)

-

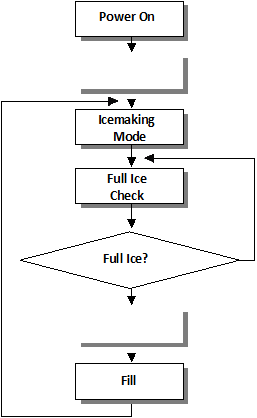

ICEMAKER OPERATING METHOD AND TROUBLE SHOOTING

- Icemaker’s Basic Operating Method

Adjusts Ice Tray to Start Position with power on.

Adjusts Ice Tray to Start Position with power on.

-

Waits until water becomes ice.

Waits until water becomes ice.

For cold air circulation, Ice tray will be on a slightly tilt one hour after

For cold air circulation, Ice tray will be on a slightly tilt one hour after

ice-making mode begins. Atilt ice tray means icemaker’s normal operation.

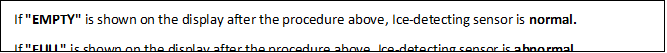

If water becomes ices in the ice tray, Ice-detecting sensor check if the ice bin is full.

If water becomes ices in the ice tray, Ice-detecting sensor check if the ice bin is full.

Twist the ice tray to drop ice into the ICE BIN.

Twist the ice tray to drop ice into the ICE BIN.

Supply water to the ice tray by operating the solenoid valve.

Supply water to the ice tray by operating the solenoid valve.

-

To force water to supply to the ice tray, or check icemaker’s condition press and hold the FILL Key for about 3seconds.

To force water to supply to the ice tray, or check icemaker’s condition press and hold the FILL Key for about 3seconds.

In the test mode, The icemaker will run through 3 stages step by step

: Harvest

Fill water

Ice making

To reset the icemaker’s operation, set the power switch OFF position and back it to ON position.

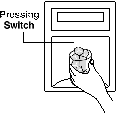

Power Switch

Power Switch

Icemaker Unit

- ICE MAKER FUNCTIONS

- Icemaking Mode

- Icemaking Mode begins right after the ice tray fills with water.

-

Icemaker waits until water becomes ice in the ice tray.

Ice-detecting sensor checks if the ice bin is full every 2min.

-

Harvest Mode

At least in 110min, since icemaker begun icemaking mode, Icemaker starts to twist the ice tray to drop ices into the Ice bin. (After installation, at least 1day is needed to make ices)

If the icemaker never drop ices to the ice bin though water becomes ices in the ice tray, check the real temperature of compartment. (not temperature on display)Icemaker needs below 0°F to drop ices to ice bin.

-

-

Fill/Park Position

Once the normal harvest mode has been completed, the water solenoid will be activated.

-

Trouble Shooting Ice & Water system Issues

- Icemaker not making ice or not making enough ice (Environmental Diagnosis)

Icemaker can’t make ices itself. Basically, water, temperature and time are needed.

- Water : If no Water, then no Ice.

- Temperature : The compartment, where the icemaker is located, has to be at least 1°F so that icemaker dumps ices to the bin.

- Time : At least 80 minutes must be passed to make one series of ices after water comes into icemaker.

Test Mode should not be carried out before checking below.

Test Mode should not be carried out before checking below.

|

Not making ice |

||||

| er | ||||

|

Is the icemaker’s tray filled with water or Ice? |

No |

|||

| emperature |

Yes |

|||

|

Is the temperature below 10 degrees F in the icemaker compartment. |

No |

|

| ime |

Yes |

|

|

Advise the customer on how long it takes to make ice. |

||

|

No |

|

|

-

Icemaker not making ice or not making enough ice (Icemaker Unit & Ice-detecting sensor Diagnosis)

Icemaker Unit and Ice-detecting sensor Diagnosis

The icemaker unit and Ice-detecting sensor is programmed to be diagnosed.

Follow the procedure step by step to check to see if icemaker and Ice-detecting sensor is working normally.

Icemaker Unit

Icemaker Unit

Ice-detecting sensor

Test Switch

1stSTEP (Icemaker Unit Diagnosis)

Press the test switch (located on the bottom of the icemaker head) for about 3 seconds. The icemaker tray should turn to the twisting position and return to the flat position, the fills with water.

CAUTION: Be sure that the ice tray is not filled with water before pressing fill key.

CAUTION: Be sure that the ice tray is not filled with water before pressing fill key.

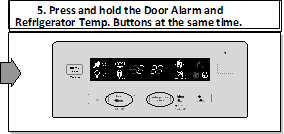

2stSTEP (Ice-detecting sensor Diagnosis)

-

Icemaker not making ice or not making enough ice (Other Suspected Items)

Strongly suspect items below If the issue remains yet, though all the diagnosis for icemaker has been carried out.

- Cap duct bad sealing

- Defective thermal sensor in the icemaker compartment

- Not cold icemaker compartment area (sealed system)

-

Not Dispensing Ice

Clogged Ice In the Ice Bin (suspected items)

-

Customer haven’t used ice dispenser over a week.

Resolution : the ices gets stuck if customer doesn’t use ice dispenser.In this case, empty the ice bin and wait until the new ices are stacked in the ice bin.

-

Temperature of icemaker compartment is not cold enough.

Resolution : Check ice fan, sealed system, cap duct, vent and other items related to temperature. -

Cap duct doesn’t seal the air properly.

Resolution : Possibly, warm air could get into the compartment and make ices get stuck. Replace the cap duct with new one. -

In-door geared motor doesn’t work

Resolution : Change the in-door geared motor and test it.

-

The water comes out of fill cup and the water get into the ice bin.

Resolution : The water pressure from shutoff valve is too high.Recommend to use regulator to the customer and close the shutoff valve slightly.

Clogged Ices In the Chute (suspected items)

-

Cap duct doesn’t seal the air properly.

Resolution : Possibly, warm air could get into the compartment and make ices get stuck. Replace the cap duct with new one.

- DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM

-

FUNCTION

- Function

-

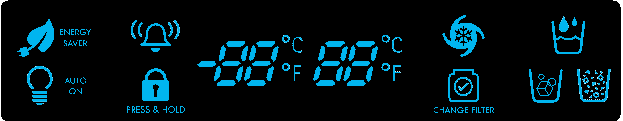

When the appliance is plugged in, it is set to 37°F for Refrigerator and 0°F for freezer.

You can adjust the Refrigerator and the Freezer control temperature by pressing the ADJUST button.

- When the power is initially applied or restored after a power failure, it is set to Control temperature Previously.

- If you do not press any button after turning on the power, only the water, Ice type, lock Icon that has been selected will be turned on and all other LEDs on the Dispenser Panel will be turned off Within 60 seconds. (Power Save Mode)

- If you press a button, only the water, Ice type, lock Icon that has been selected will be turned on and all other LEDs on the Dispenser Panel will be turned off Within 20 seconds. (Power Save Mode)

- If you do not want to use the Power Save Mode, you can change the Mode by pressing the ULTRA ICE Button and Freezer TEMP button simultaneously for more than 5 seconds.

-

How to Toggle the Display between °F & °C

1. The initial setting is °F and the display temperature mode can be changed from °F to °C or °C to °F by pressing and holding the FRZ TEMP and the REF TEMP keys at the same time for over 5 seconds.

-

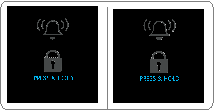

Alarm/Lock function (dispenser and display button lock)

- When the refrigerator is first turned on, the buttons are not locked. “LOCK” is deactivated with light off.

-

To lock the display, the dispenser, and the control panel, press

and hold the LOCK button for 3 seconds. “LOCK” is activated with light on.

- The LOCK button is the only control feature that remains active in the locked state. The buzzer sound, other control buttons, and the dispenser are deactivated.

- To release from the locked state, press and hold the LOCK button again for 3 seconds.

-

If you don t hold the Alarm/Lock button more than 3 seconds,

If you don t hold the Alarm/Lock button more than 3 seconds,

Alarm function will be changed and alarm for opened door will be on/off same as alarm icon indicating.

Ex) In selecting “LOCK”

Ex) In selecting “LOCK”

Ex) In selecting “LOCK” again

-

Filter condition display function

- There is a replacement indicator light for the filter cartridge on the dispenser.

- Water filter needs replacement once six months or of using water filter.

- When the Water Filter Icon lights on, you must exchange the filter.

-

After replacing the filter, press and hold the lock button for more than 3 seconds .

After then water Filter icon turn off with reset status.

Classification

Filter Status Display

Filter Status Display

- Ultra Ice selection

Please select this function for quick freezing.

Please select this function for quick freezing.

When you press the Ultra Ice Button, the Ultra ICE ICON will be turned on again.

When you press the Ultra Ice Button, the Ultra ICE ICON will be turned on again.

- Ultra Ice function automatically turns off after a fixed time passes.

-

Dispenser use selection

You can select water or ice.

When you press the Water Button, the Water Icon will be selected.

When you press the Water Button, the Water Icon will be selected.

- When you press the Ice button, the Cube/Crush ICON will be selected in order.

Hold your cup in the dispenser for a few seconds after dispensing ice or water to allow the last pieoes of ice or drops of water to fall into the cup.

Hold your cup in the dispenser for a few seconds after dispensing ice or water to allow the last pieoes of ice or drops of water to fall into the cup.

-

When after initially establ ishing the water comes out, the water tank inside fills and until at the time of quality the hour is caught.

-

DISPENSER LIGHT

– Whenever pressed the LIGHT button, DISPLAY is changed as belows.

Normal status : Ambient Light is off.

AUTO status : Detecting the lighting of room by LIGHT SENSOR, Ambient Light is on and off automatically. ON status : Ambient Light is on continuously.

AUTO status : Detecting the lighting of room by LIGHT SENSOR, Ambient Light is on and off automatically. ON status : Ambient Light is on continuously.

For all status : When dispenser is operated, DISPENSER LIGHT is on.

-

CONTROL OF FREEZER FAN MOTOR

- Freezer fan motor has high and standard speeds.

- High speed is used at power-up, for Ultra Ice, and when refrigerator is overloaded. Standard speeds is used for general purposes.

- To improve cooling speed, the RPM of the freezer fan motor change from normal speed to high.

- High speed (2700RPM) : Initial power on or load corresponding operation, Ultra Ice. Normal speed (2400RPM) : General working conditions.

-

Cooling Fan Motor

- The cooling fan is switched ON and OFF in conjunction with the compressor.

- The cooling fan Motor has high and standard speeds. (When room temper rapture more high then 38°C speed is high)

-

The Failure sensing method is the same as in the fan motor of the freezing fan motor(refer to failure diagnosis function table for failure display).

-

Ice Compartment Fan

-

- The Icing Fan is controlled by the the sensor on the top of the ice compartment.

- The Failure sensing method is the same as in the fan motor of the freezer (refer to failure diagnosis function table for failure display)

-

Refrigeration room Fan Motor

- The refrigeration room fan is switched ON and OFF in conjunction with the refrigeration room temperature.

- The Failure sensing method is the same as in the fan motor of the freezing fan motor (refer to failure diagnosis function table for failure display).

-

Ultra ICE

- The purpose of this function is to intensify the cooling speed of freezer and to increase the amount of ice.

- Whenever selection switch is pressed, selection/release, the Icon will turn ON or OFF.

- If there is a power outage and the refrigerator is powered on again, Ultra ICE will be canceled.

- To activate this function, press the Ultra ICE key and the Icon will turn ON. This function will remain activated for 24 hrs. The first one hours the compressor, Freezer Fan and Icing Fan(high speed) will be ON. The next 23 hours the Ice room will be controlled at the lowest temperature. And icing fan run high speed. After 24 hours or if the Ultra ICE key is pressed again, the Ice room will return to its previous temperature. And icing fan run standard speed.

-

During the first 1 hours :

- Compressor, Freezer Fan and Icing Fan(high speed) run continuously.

- If a defrost cycle begins during the first 30 minutes of Ultra ICE, the Ultra ICE cycle will complete its cycle after defrosting has ended.

If the defrost cycle begins when Ultra ICE has run for more than 30 minutes, Ultra ICE will run for 40 minutes after the defrost is completed.

- If Ultra ICE is pressed during defrost, Ultra ICE Icon is on but this function will start seven minutes after defrost is completed and it shall operate for one hours.

- If Ultra Ice is selected within seven minutes after compressor has stopped, the compressor (compressor delays seven minutes) shall start after the balance of the delay time.

- Compressor, Freezer Fan and Icing Fan(high speed) run continuously.

- For the rest of the 23 hours, the Ice room will be controlled at the lowest temperature. And icing fan run high speed.

-

How to set the display mode and cancel it

- With the refrigerator door open, keep pressing the Refrigerator Temp Button and ULTRA ICE Button more than 5 seconds, then it goes to the display mode with Special Beep Sound.

- Perform the same way again to cancel the display mode.

- All freezing units do not work at the display mode.

-

Energy Saver

- If you want additional power save, you can turn on energy saver (some heater off for anti-dew).

- To turn on or off the energy saver function, press Energy Saver Button for more than 3 seconds.

- We recommend using energy saver function when you go out for quite a long time and are out of the rainy season.

Pillar Heater Off

Pillar Heater On

Pillar Heater On

- Defrosting (removing frost)

- Defrosting starts each time the COMPRESSOR running time Betwee 7~50 hours.

- For initial power on or for restoring power, defrosting starts when the compressor running time reaches 4 hours.

- Defrosting stops if the sensor temperature reaches 46.4°F(8°C) or more. If the sensor doesn’t reach 46.4°F(8°C) in 1 hours, the defrost mode is malfunctioning. (Refer to the defect diagnosis function, 8-1-15.)

- Defrosting won’t function if its sensor is defective (wires are cut or short circuited)

-

Defect Diagnosis Function

- Automatic diagnosis makes servicing the refrigerator easy.

- When a defect occurs, the buttons will not operate; but the tones. such as ding. will sound.

- When the defect CODE removes the sign, it returns to normal operation (RESET).

- The defect CODE shows on the Refrigerator and Freezer Display.

-

LED check function: If simultaneously pressing Ultra Ice button and freezing temperature adjustment button for a second, display LED graphics on. If releasing the button, the LED graphic displays the previous status.

You can check the error code Within 3-hour Period from initial error

-

Auto pantry

- The temperature control will automatically start upon the selected Auto Pantry temperature control.

- You can adjust the Pantry control with three different temperature ranges by pressing the activate button.

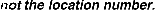

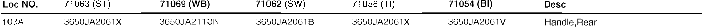

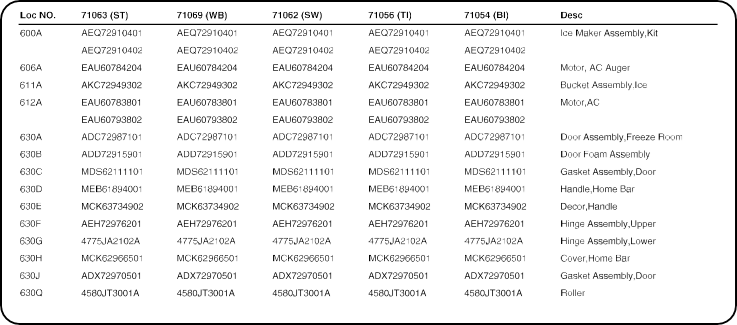

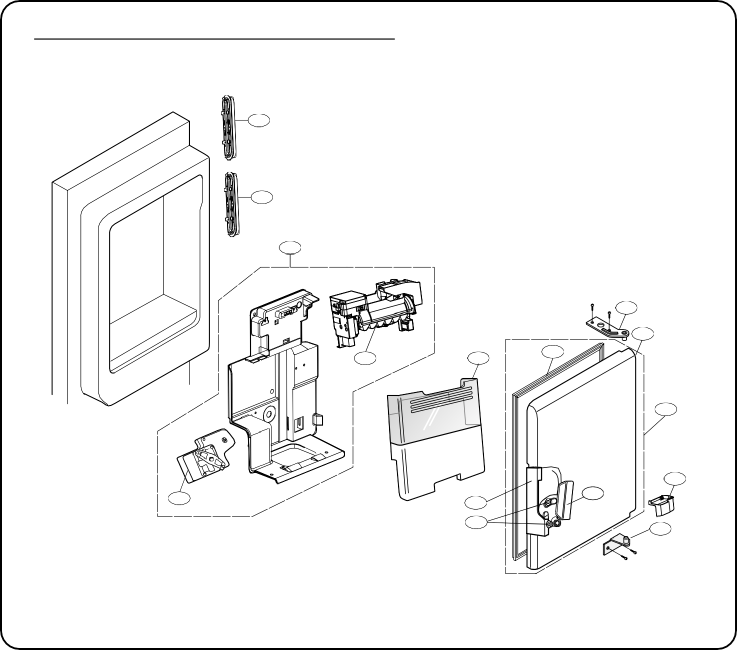

CASE PARTS

CAUTION : Use the part number to order the part, not the position number.

603E

603C

626A

624E

624D

207B

S03

402A

503E

503D

S11

S01

624C

500P

624A

503G

409D

501F

S02

S01

103A

103B

207A

S03

402A

B01

271B

120A

158A

S11

501G

610D

B01

406D

405G

329B

145A

120C 282G

120B

405E

411A

500A

410J

500H

313A

S02

271D S10

145B

S11

262B

405D

404B

405C

405H

405F

405I

282F

S11

262H

406B

B02

S14

302B

400A

316A

314A

300A

318A

105A

317A

303A

304A

249D

S14

B02 249C

106A

408A

316B

310B

312A

309B 329C

420A

323B

410G

312C

106A

290A

315B

145G

409B

503F

405H

405F

404A

405C

405B

329A

332C

319C S20

319A

315C

315A

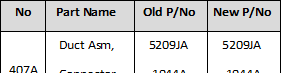

407A

610C

315C

315B

103C

S17

B04

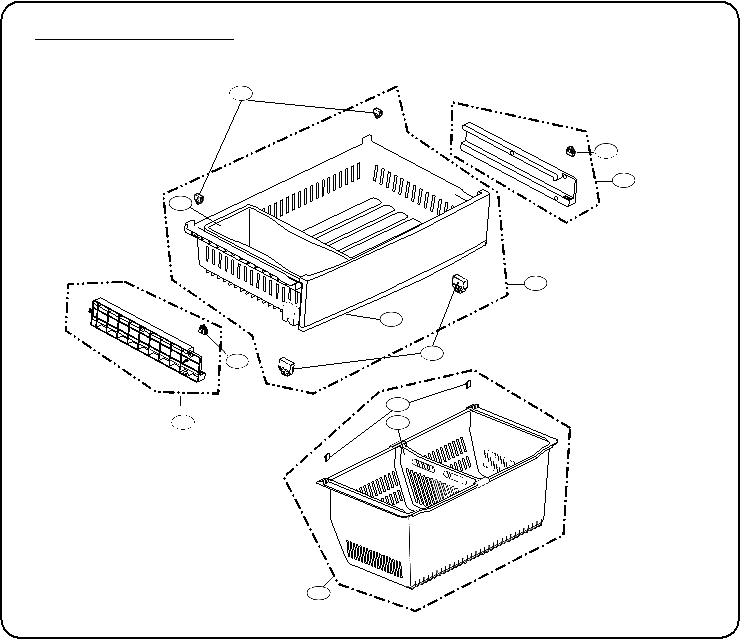

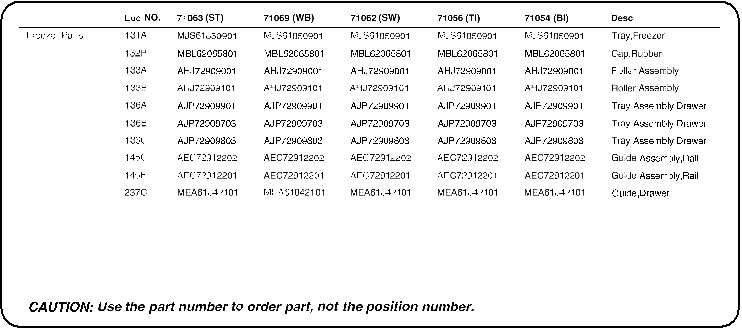

FREEZER PARTS

FREEZER PARTS

CAUTION : Use the part number to order part, not the position number.

133B

133B

145C

131A

136C

136B

133B

133A

132P

145F 237C

136A

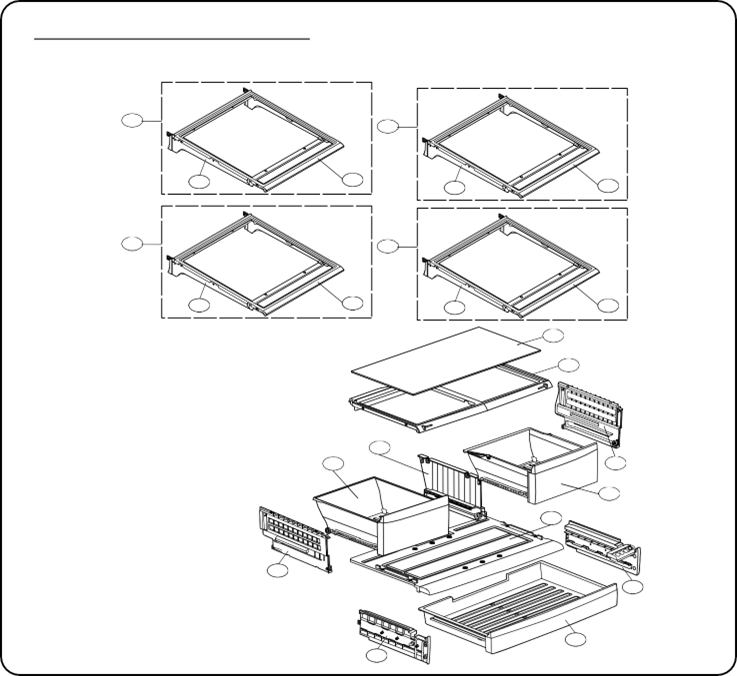

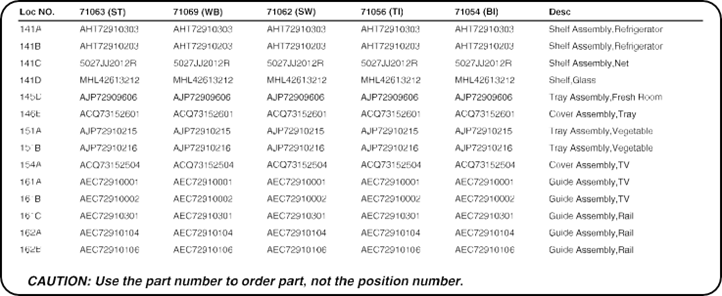

REFRIGERATOR PARTS

REFRIGERATOR PARTS

CAUTION : Use the part number to order part, not the position number.

141A

141A

141A

141A

141D

154A

151A

161C

161B

151B

146E

161A

162B

145D

162A

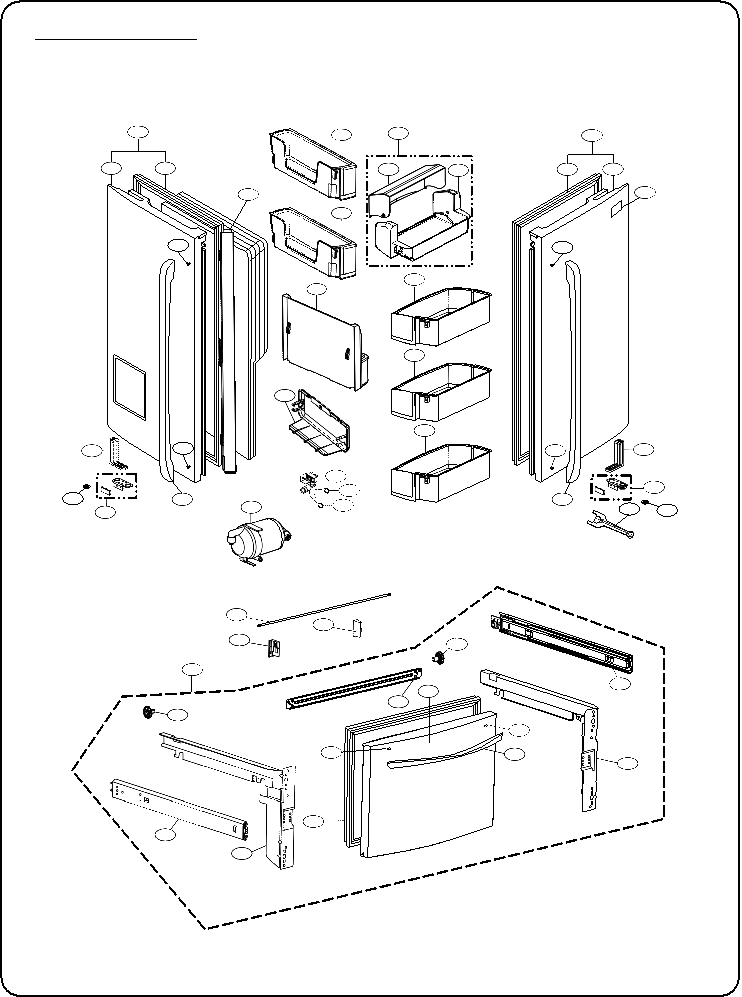

DOOR PARTS

CAUTION : Use the part number to order part, not the position number.

230B

241K

241A

230A

231B

233B

241C

241B

233A

231A

235A

212G

241K

B06

B06

241D

241G

241D

312B

243C

B06

241E

B06

243D

262C

243B

244A

615A

619B

603B

603C

244A

243A

262E 262C

250A

250H

250F

250B

250B

200A

249P

201A

249E

B06

B06 212D

249J

203A

249F

249K

630J

630J

612A

630F

630B

600A

611A

630C

630A

606A

630E

630D

630H

630Q

630G

– 10 –

REFRIGERATOR SERVICE MANUAL PDF =

Your articles are extremely helpful to me. Please provide more information! http://www.hairstylesvip.com

What’s up gamers? Been poking around on beeph and it’s got my attention. Might be worth a look for you too: beeph

Trying my luck on jljl16. Fingers crossed! Decent selection of games, so far. Check it out and see if you can win big jljl16.

Okay, so I’m looking for good customer support. Anyone had any experience with suportegalerabet? Quick responses a must!

Alanobet, alright alright alright! Be careful out there, gamble responsibly, know what I mean? If you’re gonna play, play smart. But here’s their page: alanobet

Plataforma lobo 888 saque? Cái tên nghe lạ quá à nha. Chắc là của mấy ông Tây. Thôi cứ vào xem sao, biết đâu lại gặp được em Tây xinh tươi. Give it a try plataforma lobo 888 saque.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Yo, for all my Macau peeps, 7m.cn ma cao is where it’s at for live scores. I’m just sharing what I know, man.

69wincasino… Now that sounds interesting. Always looking for a new casino to try my luck at. Might have to take a peek. Check ’em out: 69wincasino

OkeBet Login – simple and straightforward, I hope! Ain’t nobody got time for complicated logins. Let’s get to the games! Hoping for some exciting spins! okebetlogin